Retail Inbound Palletization in D365 | Approach to D365 for Commerce with Adv WH Mgmt

sumit0417

sumit0417

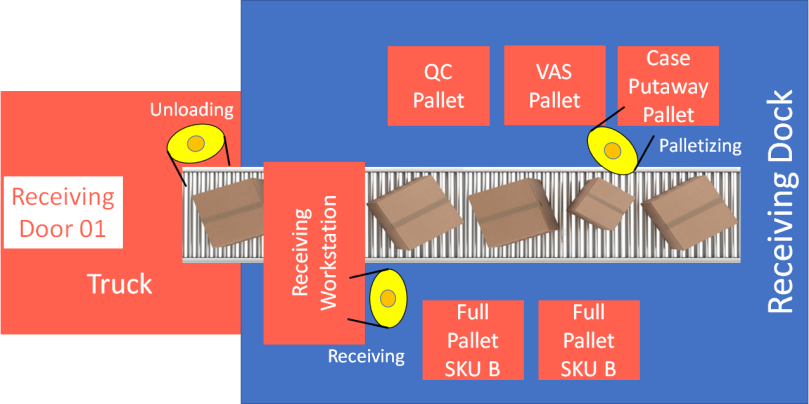

Hi Guys, Hope you have read my previous post where we talked about Retail Inbound routing using Filter codes, Disposition Codes and Barcode Receiver document and we got a better starting point for mapping the Retail Inbound business process with D365 FO. In this blog, we’re going to start off with just something pretty simple, and that’s just unloading a bunch of cases, receiving them, and then palletizing them according to whatever destinations they need to go to.

Now, keep in mind, for unloading, there really isn’t any D365 FO functionality involved. Now, they do need to have that barcode receiving document so that the receiving people can recognize that this particular product needs to be palletized because we got a bunch of cases for it. But other than that, there’s really no software there. So, let us look at how cases are palletized by destination after being received.

Now it’s time to talk about receiving. To do that, we naturally need to create a PO. Navigate to the Procurement and sourcing > All purchase orders. Create a new purchase order. We will come down here and then indicate where the purchase order will be received, which is in site DC, warehouse 26, because that’s the warehouse I’ve set up associated with the USRT company.

Enter the lines on the PO. We are going to order just one line, Mesh BMX Gloves, and it will be for 100 quantity. Hit refresh or Save to get that PO number because we want to use that in the receiving process, so it’s PO 001571.

Let us go to the Warehouse Mobile Device. I’ve created a mobile device menu item called Receive license plates that’s specially designed for receiving.

Imagine the truck is at the Inbound door, Warehouse workers starting to unload those cases. Now we have to identify a case to the system. So we have to begin by telling it the PO number. So enter the PO number created above, and then scan the barcode for the item, which is G0008. Then it will ask how many are in the box, and we can look on the outside of the box on the label and put in 100.

Now let us talk for a moment about these other two fields. The unit for the quantity is pretty obvious. But the use of disposition code is extremely important. As we talked in our earlier post, you have to be able to direct cartons in different directions. And we use the disposition code to accomplish that for those items where the receiving operator needs to send a carton to some particular area. The default is to always send it back to putaway case, which means it’s going to go to the case storage area. However, there’s lots of other options. If we want to send it to value-added services if it’s a pallet or we want to send it to QC, and we have all those available to us. But for now we will select ToPACase.

Now it’s asking us for license plate that’s on the box, and we will type in the license plate number LP00157101. And it’s been received.

Now what we can do is we can go to the Warehouse Management module, we can look at the work that has been created as a result of bringing this product into the building which has been received.

- Navigate to Warehouse Management > Work > Inbound > Open Purchase Work.

- Select the Open Work for PO 001571.

- It needs to be now moved to the next step in the receiving process, which is palletizing, and it needs to go to the location R2PC01.

So now we need to move to the second step of the receiving process. If you’ll remember, there’s a receiving operator followed by a palletizing operator.

So now we need to palletize this product. So let us go back to the mobile device terminal. Choose Palletize IB Case mobile device menu item that’s specially designed for Palletizing.

So we’ll type in the license plate number LP00157101. And now the system is going to tell the palletizing operator where to put that case.

And you can see that it’s confirming that is this the one you got?

So where’s it supposed to go? It’s telling us to put it into R2PC01. So this is a pallet that’s located at the dock right there next to the receiving station that’s going to the case storage area. And the reason is because we’ve designed these locations so that if it has an R2PC that means receiving to putaway case. So I know that’s where it needs to go. So I’m going to put it in that location on the pallet that’s resting there. So I just need to type in the location check digit. And probably in the actual implementation you’ll use check digits that is printed on the wall as a barcode to confirm that you put it in the correct location.

So with that, we will see now when we go back and we look at the work that’s outstanding for this by navigating to Warehouse Management > Work > Inbound > Open Purchase Work. We can see that the first step in the process of getting this case into the building has been completed. So there was a move from RECV to R2PC01, and that task is now closed. So now the next step of the process will be putaway.

Alright, before we leave palletization, we’ve got to talk about another requirement and how D365 FO is used to fulfill that one. Now, in our earlier post on Palletization business process, there were two things that they needed to have fulfilled. One was they needed to have some way of looking at a box and figuring out where it needed to be palletized. And we just finished the process of scanning a box and having the system tell you where to put it. The second requirement was as these cases get added to the pallet, you need to have some way of signaling that this pallet is ready to go, that it’s ready to be moved to whatever destination it needs to go to. Well, what I suggest you do is something very practical. Once the pallet is ready to go, just put a big orange cone on the top of it and a placard with the destination listed on the side. And that’s the signal that someone will realize when they’re driving along the dock and see a pallet with a cone on it, they can move it and this is where it needs to go. It’s very simple and it’s a very common procedure used in lots of Retail Warehouses around the world.

So I hope you got a better understanding on the Retail Inbound palletization operation in D365 so it is easier for you when you go and implement the D365 FO Warehouse management module for the Retail Inbound processes.

In the next blog, we’re going to next destination in Inbound side of the Retail Warehouse once the palletization is completed and ready to move to Case Putaway.

Feel free to reach out for any clarifications. If you like my blog posts then comment and subscribe to the blogs.

#RetailDAXing #D365Commerce

Disclaimer: The information in the weblog is provided “AS IS”; with no warranties, and confers no rights. All blog entries and editorial comments are the opinions of the author.

Credits: Microsoft Learn, Microsoft Docs

This was originally posted here.

Like

Like Report

Report

*This post is locked for comments