Good Afternoon D365 Community :)

We try to use Purchase order workflow and we face some strange things with the Remainder quantity and ordered quantity.

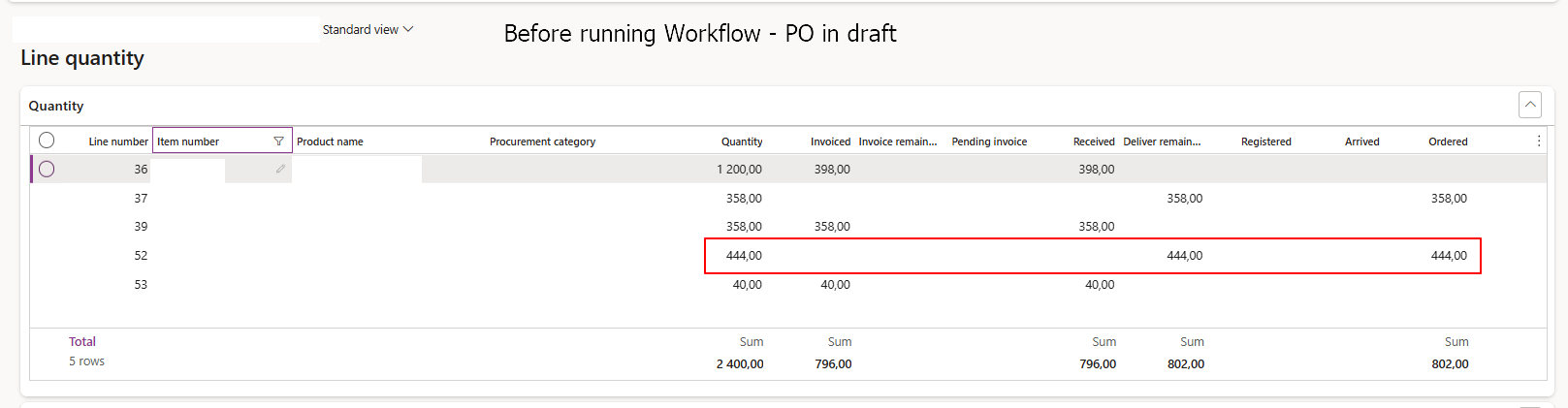

print screen below are for one item only, with different delivery scheduled done manually or with Landed cost module.

This is the quantity we have when we make modification on PO, so status is in Draft:

without any modification, we submit workflow again, status change to approved without any error, and now quantities looks like that :

Do you have any idea about what can change this by running the workflow ?

We have a test environnment but I can't reproduce this... test environnement was refresh a few months ago, should not have any difference in the setup. I compare both worfklow and not difference at all. it is quite basic with automatic approval if amount of PO is less than 100k and more than 100k less than 400k purchase manager needs to approve and more than 400k purchase manage and director must approve PO.

We add a purchasing policies to make an automatic approval if nothing change on the PO, only a change on the vendor will need a new approval from purchase manager and director according to the amount...

Many thanks in advance for your suggestion and help.

Have a nice day,