Hi ,

Important remarks :

- All assembly items for the customer have assembly policy = Assemble-to-Stock.

- I found how to generate new assembly orders via the planning worksheet (this is not a problem).

- I am able to post assembly orders without error.

- (I read through the related MS Docs documentation, most is related to Assemble-to-ORDER. What I need is information about Assemble-to-STOCK :

Question : Items with policy : "Assemble-to-stock" :

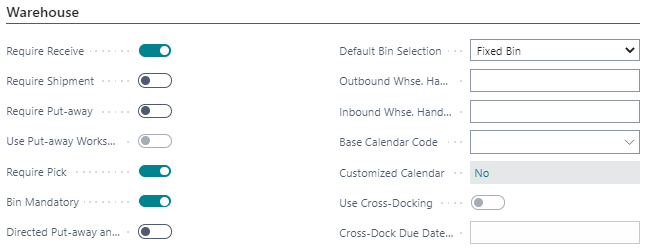

If my location setup works with only :

- Require receive = yes (= warehouse receipt)

- Require pick = yes (= inventory picks)

- bin mandatory = yes

Before posting the assembly order ,

the warehouse worker needs to be able to first "Take" the required components from the warehouse & "Place" them

on a BIN so that the components can be consumed in assembly. As I understand in standard BC this can be done via inventory movement only.

--> Microsoft documentation : Components for assembly orders cannot be picked or posted with inventory picks. Instead, use the Inventory Movement page.

Description of scenario :

1) Assembly order > release

2) Assembly order > warehouse > create inventory movement

3) ERROR : "there is nothing to create"

I tried different things already , but I always get same error "there is nothing to create"...

Additional info:

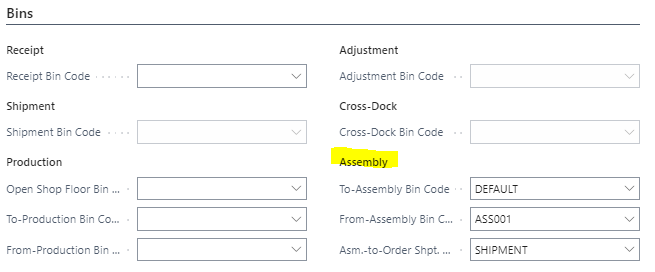

All of the available inventory (stock) is on the same Location & same BIN ("DEFAULT")

For that location , I also have a BIN "ASS001" where via inventory movement the component items should be placed.

Location setup : (warehouse fasttab)

I am working with basic BC flow , tested & working.

- Purchase orders : Warehouse receipt

- Sales orders : inventory pick

Location card > Bins (fasttab)

Kind regards,