Hi Pranav Teja Kasinadhuuni,

Maintenance rounds are used to schedule those job types which are to done in a regular interval. You cannot add job types like inspection of pressure gauges, lubrication levels of gears and cleaning condition inspection of assets in maintenance plans.

These task are basic task which are need to keep an eye on overall asset performance.These task determine that if there is a need to schedule a maintenance plan earlier.

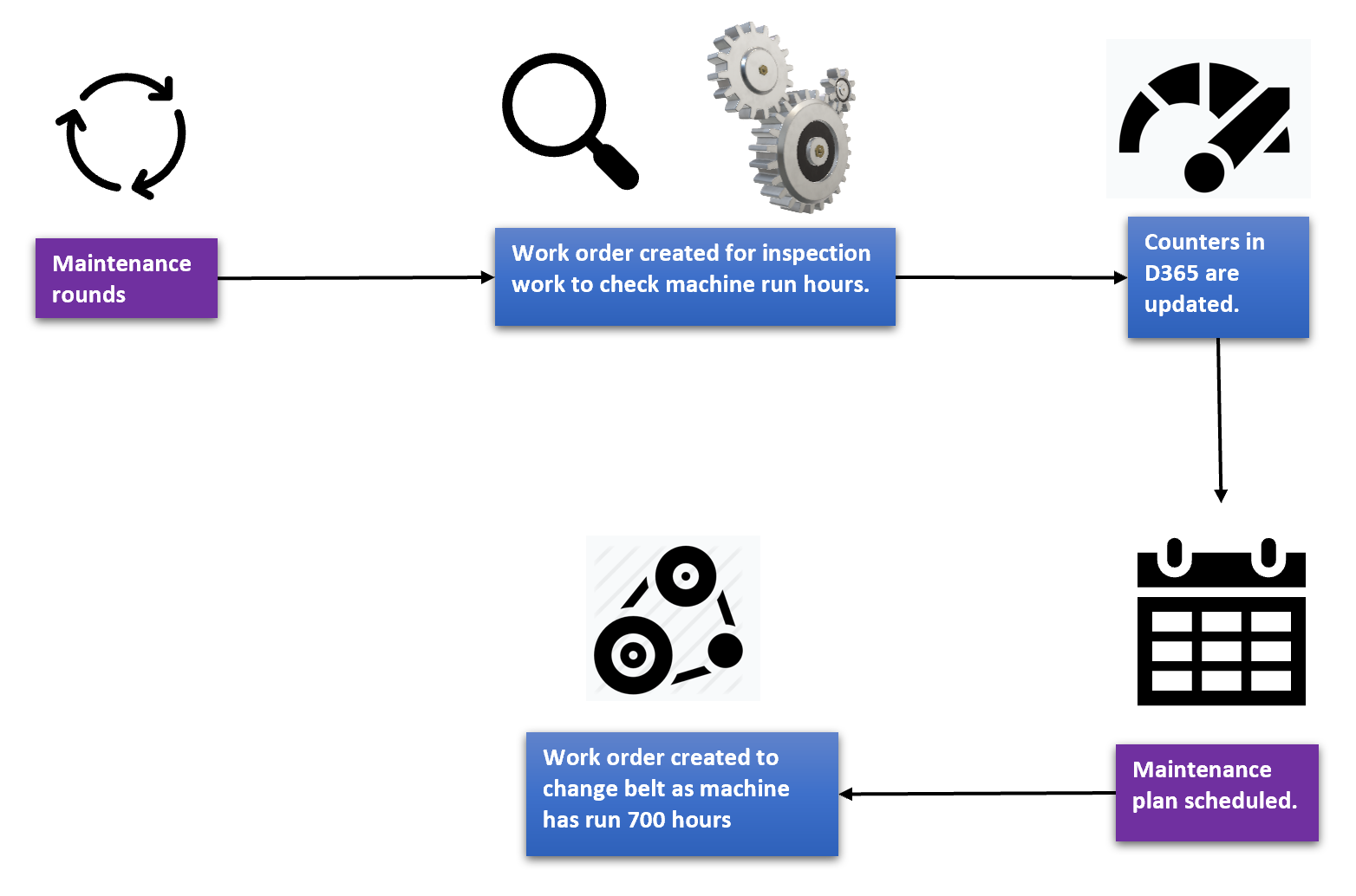

So to give an example I will setup rounds for inspection of total run time of a machine using maintenance rounds. Post the inspection the collect data will be updated in the counter in D365.

As counter is updated this will trigger maintenance plan once counter max limit is reached.

There are so many ways you can use them. I have shared on example with you.

So if for a machine we have a recommendation from supplier that varriator belt should be changed every 700 hours then i will make a maintenance round for weekly inspection of the machine run time since last change and the recorded value will be updated in counter in D365.

Once counter reaches 700 hours maintenance plan will generate a work order to change belt.