Hello,

Below is a very long overview of the planning parameters and how they work. Hope this helps.

The way in which the planning system controls item supply is determined by various settings on the item card or SKU, and settings in manufacturing setup. The following table shows how these parameters are used for planning.

|

Purpose

|

Parameter

|

|

Define if the item is to be planned

|

Reordering Policy= Blank

|

|

Define when to reorder

|

Time Bucket

Reorder Point

Safety Lead Time

|

|

Define how much to reorder

|

Safety Stock Quantity

Reordering Policy:

• Fixed Reorder Qty. plus Reorder Quantity

• Maximum Qty. plus Maximum Inventory

• Order

• Lot-for-Lot

|

|

Optimize when and how much to reorder

|

Rescheduling Period

Lot Accumulation Period

Dampener Period

|

|

Modify the supply orders

|

Minimum Order Quantity

Maximum Order Quantity

Order Multiple

|

|

Delimit the planned item

|

Manufacturing Policy:

• Make-to-Stock

• Make-to-Order

|

Define If the Item Will Be Planned

To include an item/SKU in the planning process, it must have a reordering policy otherwise it must be planned manually, for example, with the Order Planning feature.

Define When to Reorder

Reorder proposals are generally released only when the projected available quantity has fallen to or below a given quantity. This quantity is defined by the reorder point. Otherwise, it will be zero. Zero can be adjusted by entering a safety stock quantity. If the user has defined a safety lead time, it will cause the proposal to be delivered in the period prior to the required due date.

The Time Bucket field is used by reorder point policies (Fixed Reorder Qty. and Maximum Qty.), where the inventory level is checked after each time bucket. The first time bucket begins on the planning starting date.

The default safety lead time, in the Manufacturing Setup window, should be set to at least one day. The due date of the demand may be known, but not the due time. The planning schedules backward to meet gross demand, and, if no safety lead time is defined, the goods may arrive too late to meet the demand.

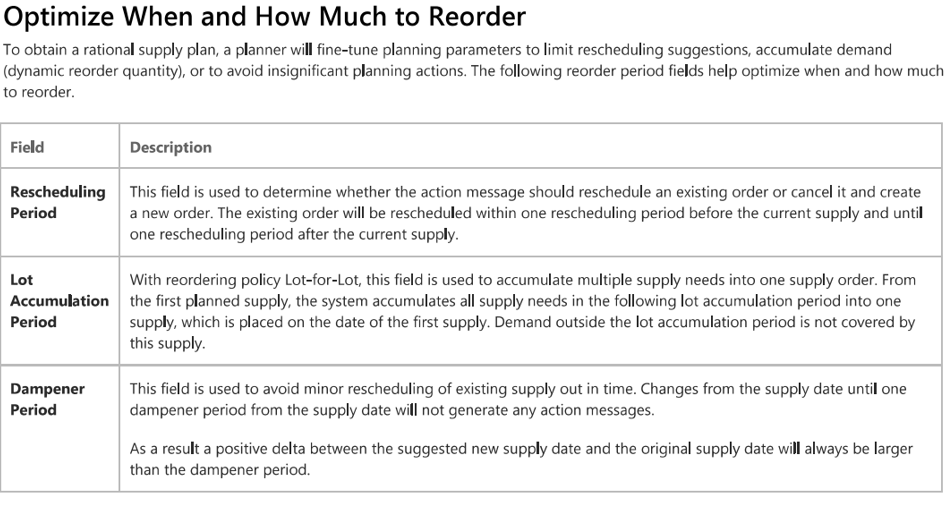

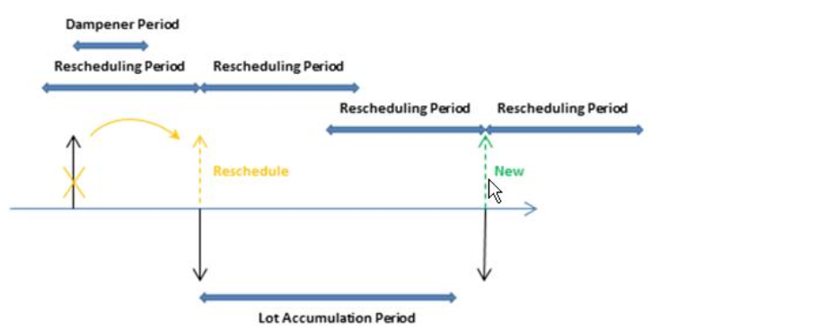

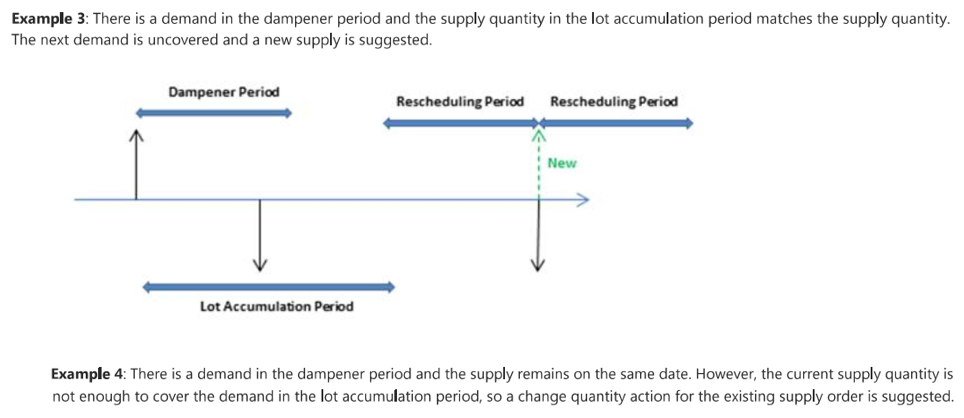

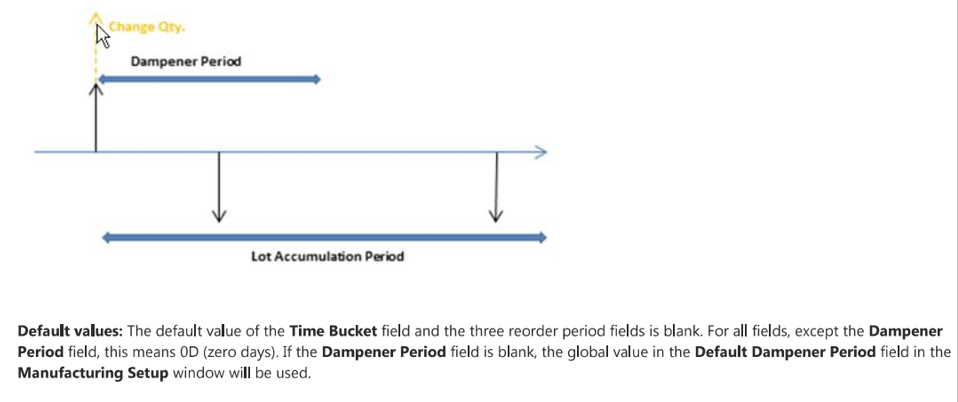

Three additional reorder period fields, Rescheduling Period, Lot Accumulation Period, and Dampener Period, also play a role in defining when to reorder.

Define How Much to Reorder

If the planning system detects the need to reorder, the selected reordering policy is used to determine when and how much to order. Independent of the reordering policy, the planning system usually follows this logic:

- The quantity of the order proposal is calculated to meet the specified minimum inventory level of the item, usually the safety stock quantity. If nothing is specified, the minimum inventory level is zero.

- If the projected available inventory is below the safety stock quantity, a backward-scheduled supply order is suggested. The order quantity will at least fill the safety stock quantity, and can be increased by gross demand within the time bucket, by the reordering policy, and by the order modifiers.

- If the projected inventory is on or below the reorder point (calculated from aggregated changes within the time bucket) and above the safety stock quantity, a forward-scheduled exception order is Both the gross demand to be met and the reordering policy will determine the order quantity. At minimum, the order quantity will meet the reorder point.

- If there is more gross demand due before the ending date of the forward-scheduled order proposal, and this demand brings the currently calculated projected available inventory below the safety stock quantity, the order quantity is increased to make up the deficit. The suggested supply order is then scheduled backward from the due date of the gross demand that would have violated the safety stock quantity.

- If the Time Bucket field is not filled in, only the gross demand on the same due date will be added.

The following reorder period fields also play a role in defining how much to reorder: Rescheduling Period, Lot Accumulation Period, and Dampener Period.

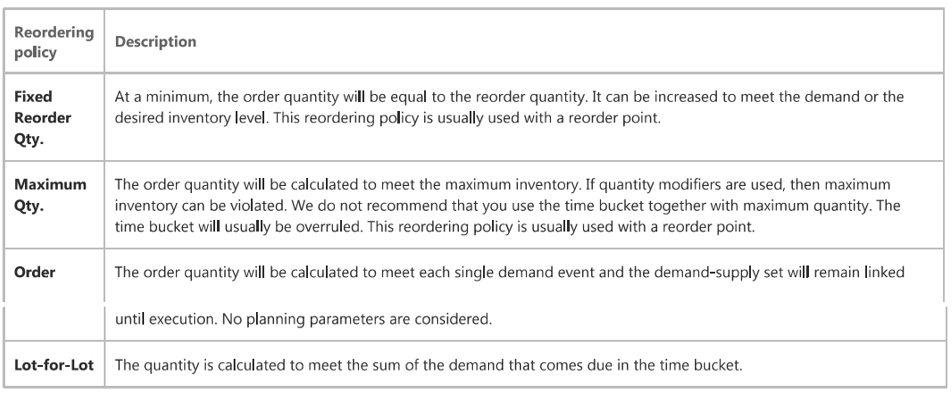

Reordering Policies

The following reordering policies affect the quantity that is being reordered.

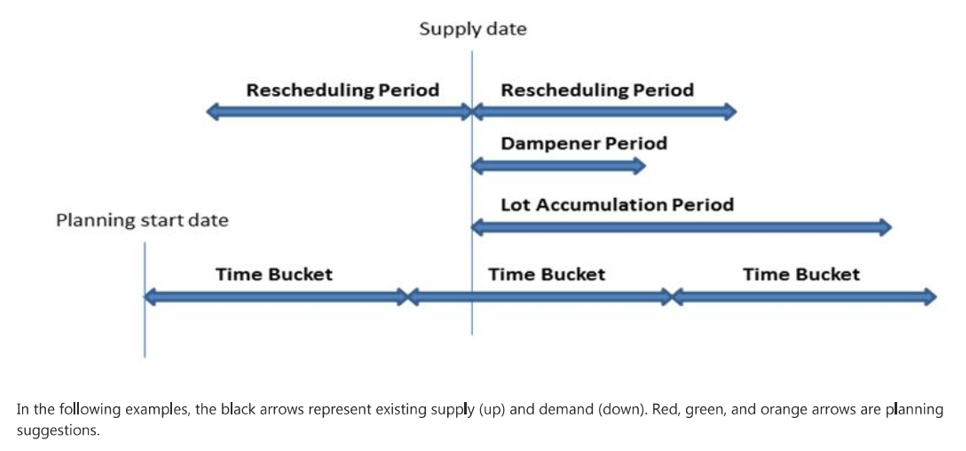

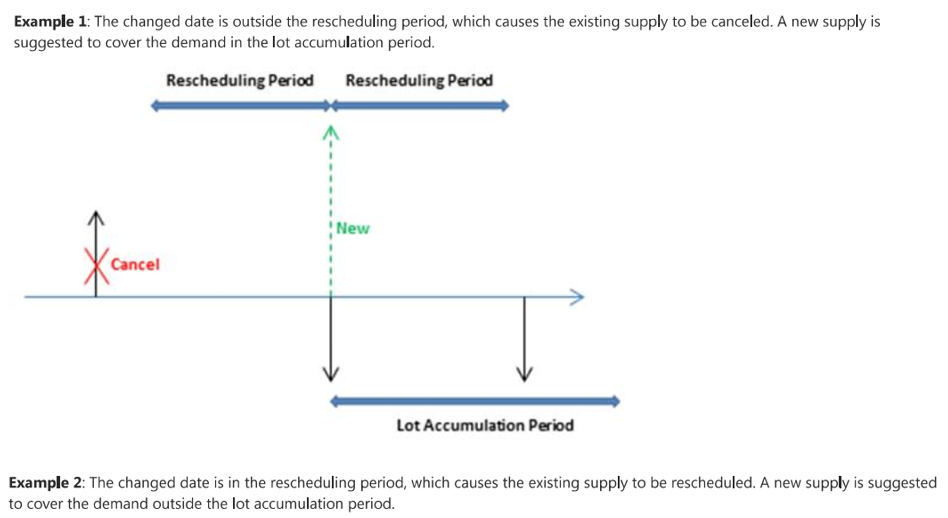

The timing of rescheduling period, dampener period, and lot accumulation period is based on a supply date. The time bucket is based on the planning start date, as shown in the following illustration:

Blank Overflow Level

Defines how the planning system should react if the Overflow Level field on the Item of SKU card is empty. You can select from the following options:

- Use Item/SKU Values Only: The blank value in the Overflow Level field of the Item or SKU is respected, and the overflow level is not used

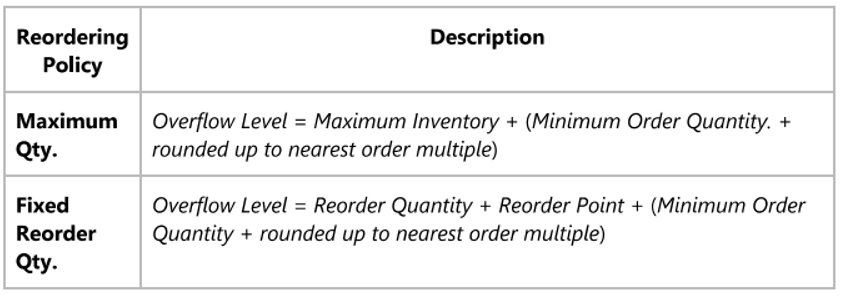

- Allow Default Calculation: The overflow level is calculated as follows for items that use the two supported reordering policies:

Modify the Supply Orders

When the quantity of the order proposal has been calculated, one or more of the order modifiers can adjust it. For example, the maximum order quantity is larger than or equal to the minimum order quantity, which is larger than or equal to the order multiple. The quantity is decreased if it exceeds the maximum order quantity. Then, it is increased if it is below the minimum order quantity. Finally, it is rounded up so that it matches a specified order multiple. Any remaining quantity uses the same adjustments until the total demand has been converted into order proposals.

Delimit the Item

The Manufacturing Policy option defines which additional orders the MRP calculates will propose. If Make-to-Stock option is used, the orders concern only the item in question. If the Make-to-Order option is used, the planning system will analyze the production BOM of the item and create additional linked order proposals for those lower-level items that are also defined as make-to-order. This continues as long as there are make-to-order items in the descending BOM structures.

Blank Overflow Level

Defines how the planning system should react if the Overflow Level field on the Item of SKU card is empty. You can select from the following options:

- Use Item/SKU Values Only: The blank value in the Overflow Level field of the Item or SKU is respected, and the overflow level is not used

- Allow Default Calculation: The overflow level is calculated as follows for items that use the two supported reordering policies

Understanding the Difference between Lead Time and Safety Lead Time

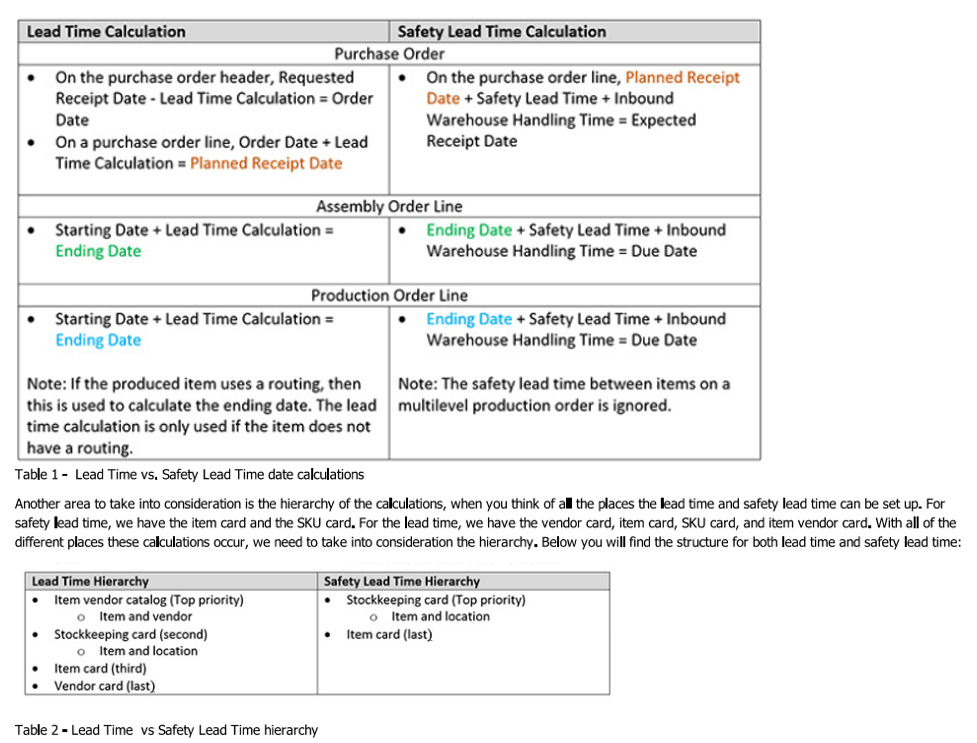

Safety Lead time is cushion time period for delays in the process. Lead time is a planning time used for the start of process to the end of the process to replenish the item. Both safety lead time and lead time have a date calculation driving the results. Here are the calculations for each:

Hope this helps.

Thanks,

Steve