GPTip42day - Purchase Order Generator - what is it?

Views (3911)

Frank Hamelly | MVP...

Frank Hamelly | MVP...

I like to call PO Generator 'mini-MRP'. Although not nearly as robust as Material Requirements Planning and limited to planning only Buy type items, PO Generator can be very useful in maintaining desired stock levels of purchased items.

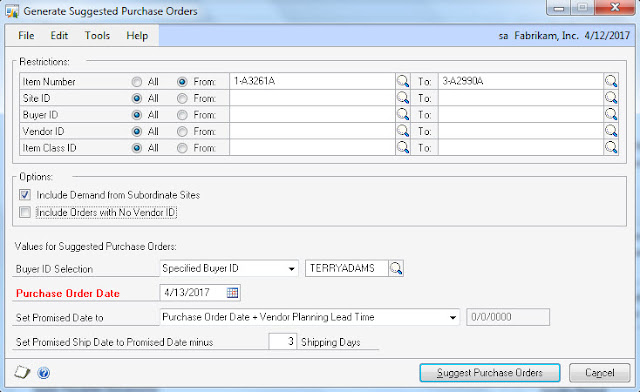

Purchasing>Transactions>Purchase Order Generator

* click image to enlarge

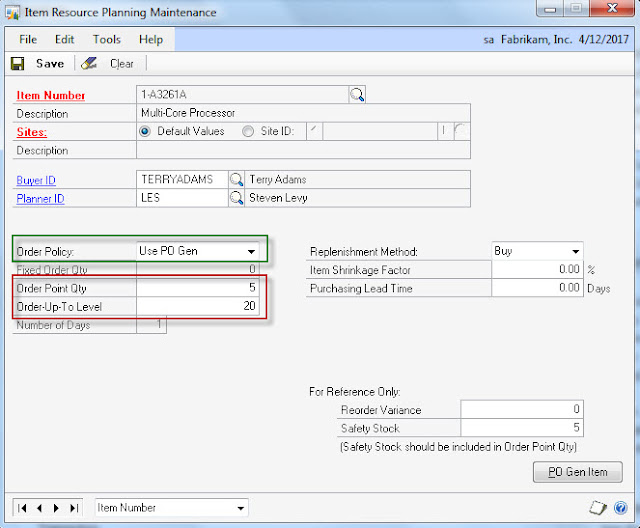

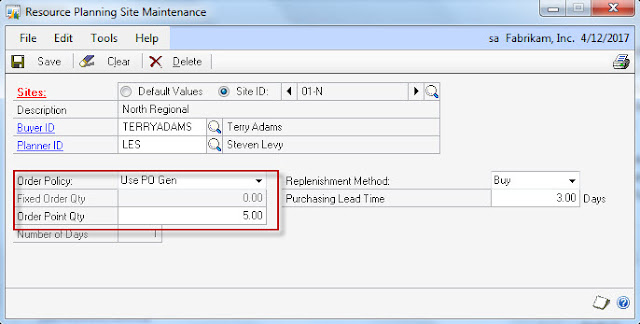

Key to determining how PO Gen plans suggested purchase orders are the settings in Item Resource Planning and Site Resource Planning.

Inventory>Cards>Item Resource Planning

* click image to enlarge

Inventory>Cards>Site Resource Planning

* click image to enlarge

The settings selected in these windows determine at what stock level PO Gen suggests purchase orders for the item/site combinations.

Essentially, PO Gen scans Available Quantity for the items and sites selected in the Generate Suggest Purchase Orders window, compares that quantity to the desired stocking level (Required Quantity) as set in the Resource Planning windows and suggests purchase orders where the Available Quantity is less than the Required Quantity. The suggested purchase quantity is based on values set in the Resource Planning windows. (For more information on how to determine these values, see Help files for Purchase Order Generator and Item Resource Planning).

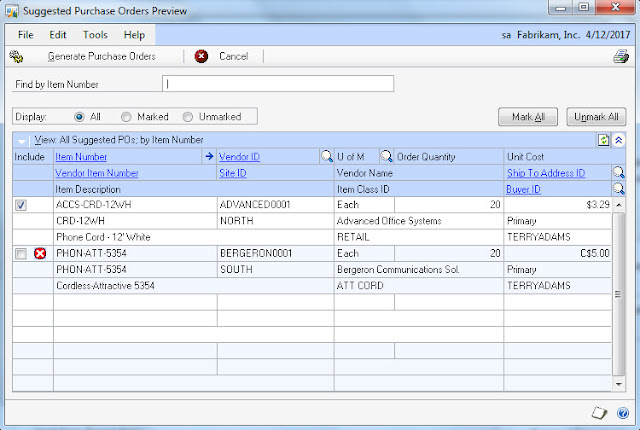

When you run PO Gen, the Suggested Purchase Orders Preview window reflects suggested POs to replenish items per your order policies.

* click image to enlarge

From this window you can generate the purchase orders required to bring your stock back up to desired levels.

Note: This is a simplistic overview of PO Generator. Please refer to the Help files and/or Printable Manuals for a more detailed explanation of how to use this planning tool.

This was originally posted here.

Like

Like Report

Report

*This post is locked for comments