IoT in D365FO (process)

id365font

id365font

In the previous article, we introduced the new functionality of D365FO that allows us to connect our IoT devices to the ERP and perform 3 types of actions:

- Monitor states and metrics

- Perform actions automatically

- Show notifications for certain events

In today's article, we will see the tool in action, show examples, and see what results D365FO proposes.

As we had mentioned before, there are currently 5 possible scenarios supported by this feature:

- Asset maintenance

- Machine status

- Downtime

- Product quality

- Production delays

For the examples, we followed Microsoft's official documentation and received some help from support groups since this is a new functionality and still needs more development.

Asset maintenance

The first scenario we are going to test will be asset maintenance. In this scenario, let's imagine that we have a device or machine connected to a certain operating cycle that requires maintenance or changing a part. The sensor of this device will periodically send us the use that this component is having, and from here we will see how the ERP reacts.

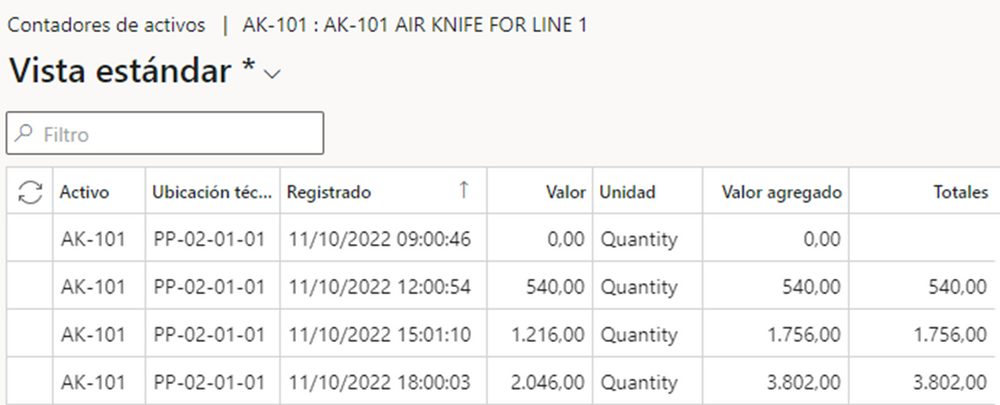

In the asset counter form, the values obtained from the sensor are automatically recorded and we see how it accumulates in the added value column.

When it reaches the configured value for that asset, a work order is automatically generated to perform maintenance on that component. This entire process is done automatically while the sensor is sending us the information.

Machine status

The second scenario to analyze will be the one that tells us the state in which our IoT device is located. In our example, we are going to imagine that we have a device from which we only want to obtain information on whether it is running or stopped (for example: a conveyor belt, an emergency light...)

As you can see in the following video, the graph shows us the number of signals that Dynamics is receiving regardless of their value. When Dynamics detects that it has not received any signal in a period of 2 minutes (configurable), it sends us a notification to let us know that the device has stopped working.

Once it receives a signal again, it notifies us in the same way that the device has returned to operation.

https://video.wixstatic.com/video/6fb605_0d54db71619c41a0a22ca574c9b5ea45/1080p/mp4/file.mp4Downtime

In the following scenario we will see how the inactivity times of the connected devices are measured. This scenario allows you to analyze the efficiency of a device by measuring usage time versus idle time. The principle is the same as for the previous case, we only need the machine to send any signal since we are not interested in its value.

We see how when it does not receive any signal for a parameterized time, it registers an inactivity time so that we can then get the standard Dynamics reports with which the performance of that asset will be measured.

Product quality

In the following scenario we will see how to monitor and control the metrics that indicate whether the products are within the quality thresholds. This scenario allows us to audit those measures that interest us in order to comply with the tolerances configured in D365FO. In this case, we are interested in the value of the measurement, since with it we will see if it complies with quality control.

In the following video you can see how for a while the sensor value is within the acceptable range for that product attribute. At a certain moment the value skyrockets and Dynamics notifies us of this so that we know that this product is not meeting the stipulated quality. Once the problem is resolved and Dynamics receives correct data again, it also notifies us so that we can make sure that the incident is resolved.

https://video.wixstatic.com/video/6fb605_d845005d70ea443e9f9f8431010c50b5/1080p/mp4/file.mp4Production delays

The last scenario allows measuring the real life cycle with the planned one to notify delays in production actions. In this scenario, it is necessary for the sensor to send us the number of units that are being produced (in this case) in order to control whether we are within the planned times or whether production is slowing down.

In the following video we can see how the curve that indicates the units produced is losing inclination, which indicates that fewer and fewer units are produced per minute. At a certain point Dynamics recognizes that at this speed we are going to have a delay in production and warns us of it.

https://video.wixstatic.com/video/6fb605_fac569cb95cf4eea89e148f85759ba6b/1080p/mp4/file.mp4¿...and now...?

Once the previous examples have been tested and we have seen that everything works correctly, we are not going to stay with this standard vision, but we are going to give it a twist.

Can you imagine that we connect an F1 to D365FO?

Could we see and control the waiting time in line at an amusement park?

What if we add an Azure tool to monitor it in real time?

I leave you a preview of the speed graph of an F1 in D365FO and I wait for you in the following article:

Like

Like Report

Report

*This post is locked for comments