Overview

Undo receipt has become a necessity in some warehouse environments where the staff may not be able to keep up with the paper flow. Strictly speaking, the undo receipt process shouldn’t be necessary because the process in place should be able to accommodate. However, if there is a situation where a department “can’t keep up”, it usually means that something is wrong within that particular department. It may not be the people, it may just be how things are being done or may just lack the manpower.

Nonetheless, while you’re trying to figure out a more efficient way in that particular department; in our case the warehouse, mistakes in receipt will be made. We need to be able to correct the mistakes in the warehouse without causing the other departments (such as accounting) a ton of headaches on reversing.

Undo Receipt

The Undo Receipt functionality is pretty straightforward. Basically, you just bring up the Posted Purchase Receipts and do the undo receipt. In fact, it’s so easy it’s explained in a step by step instruction here: Undo Receipt in Dynamics NAV

Undo Receipt with Directed Pick & Put-away

When you enable the Directed Put-away and Pick (or the full Warehouse Management in Dynamics NAV), it may be a little more complicated.

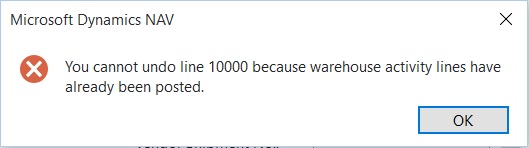

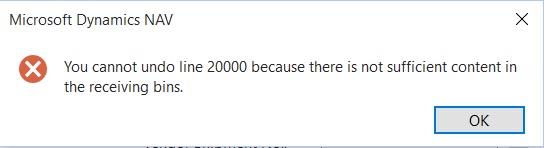

If you follow the steps on MSDN, you’ll get one of these 2 error messages:

“You cannot undo line xxxxx because warehouse activity lines have already been posted.”

“You cannot undo line xxxxx because there is not sufficient content in the receiving bins.”

One error says you do not have enough on the receiving bin for undo, the other error message says you have a put-away (registered or not) out there.

How Is This Possible?

Right now you may be asking, “how is it possible to register the put-away when it’s physically not there?”

You’re absolutely right. It is impossible to physically put-away something that you didn’t even receive. This is what makes Warehouse Management in Dynamics NAV work; it’s the accuracy of data entry from the actions performed in the warehouse. In real time!

The real problem here is the process within the warehouse receiving department. If the procedures are followed, you should never have to undo. We have to dig deeper on why the warehouse receiving staff are not following the rules for unloading the truck and putting the stuff away. Sometimes there are legitimate reasons why the procedures cannot be followed. In those cases, a new process needs to be thought out to better accommodate the receiving staff.

Resolving issues like this may take a while and this is where we spend time with the client. Often times, I wish it was as easy as just telling the warehouse people to just follow directions.

But I digress…

Undo Receipt After the Put-away is Registered

Here are the steps that need to be done in order to undo receipt after the put-away is registered.

Delete the Registered Pick:

1. Locate the Posted Purch. Receipt

2. Click on Navigate

3. Show the Posted Whse. Receipt Line

4. Click on Navigate –> Show Posted Whse. Document

5. Click on Navigate –> Registered Put-away lines

6. Click on Navigate –> Show Registered Document

7. Push Delete

Adjust the items into the Receipt Bin. In this case, our receipt bin is R:

1. Warehouse Item Journal

2. Negative adjust the item from the bin you want to take out

3. Positive adjust the quantity to the R bin

Do the undo Receipt:

1. Locate the Posted Purch. Receipt

2. Click on the line that you want to undo receipt

3. Click on Function –> Undo Receipt

Conclusion

This is just to get by until you can get to the bottom of why the receiving staff are having trouble with receiving. That’s where the real problem and the solution lies.

Like

Like Report

Report

*This post is locked for comments