I have not found a consistent resolution. In fact, I helped fix 4 production orders earlier today. However, the issue has come up SIGNIFICANTLY less in the last year and a half. The main fix is to still break the sales order line reservation and I've made it a documented general troubleshooting document for our company on how to do so.

If you would like to attempt to test out the process I know works for us, you can skip to "Solution to Try" in bold below. I provided some added information in case it helps you, or anyone else feels investigating this issue further. My first read of your post lead me to believe that you may not have tried the suggestion in my original post but, if you already know how to do it/have done it, I apologize and hope it might help someone else. I know you said "unreserving sales orders" is not part of your business process, but it might be worth following the solution below in a test environment and see if the reservation process functions the same before attempting it in prod.

Background Information/Findings:

We have only ran into this issue with items associated with quality orders generated via production order.

Here is some extra information on how our quality orders are set up for 99% of our product:

Test Groups:

General Tab:

Certificate of analysis report: Yes

Action on Failure: Fail

Acceptable Quality Level: 100.00

Update Inventory Batch Attribute: No

Test Value Determination: Blank

Test Tab:

Standard: Set

Min: Set

Max: Set

Attribute Association: Blank

Test Instrument: Set

Unit: Set (assigned to test instrument)

I'm not the one that set up how the reservations are set up, we currently use BatchAbove (batch above location) for all of our item's reservation hierarchy.

Under Modules > Inventory and Warehouse Management Parameters, under the General tab, "Reserve Ordered Items" is set to Yes and under the Quality Management tab, "Update Inventory Batch Attribute" is set to No.

Example:

Once the quality order is Validated, the above lines are no longer there and the block is released and removed from the Inventory Blocking page.

Thus, I believe what we might be facing is that D365 is not releasing the block or, not updating the inventory status/quantities, when the quality order has been validated.

Solution to Try (use a test environment first to check if the reservation behavior below is the same before attempting this in prod):

- With one tab open on the quality order, and another tab open to browse:

- Using the production order linked on the quality order (reference column), get to the corresponding Sales Order

- Highlight the sales order line corresponding to the item that's on the quality order

- Above, click "Inventory" and then "Reservation"

- On the far right side under the Reservation column, delete the quantity in the box. When cleared, hit enter or click outside of the cell.

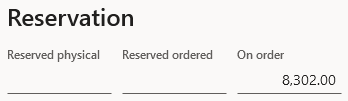

When this process is done, you'll know it "took" when the Lock Reservations box below has emptied, and any quantities in the upper left corner have moved from "Reserved Physical" and/or "Reserved Ordered" to "On Order"

Before:

After:

Before:

After:

- Return to the problem quality order and try to validate the quality order.

- Regardless of whether or not this fixed the issue, return to the reservations page.

- Click "Reserve Lot" in the upper left corner, this should move the quantities in the upper left back to where they were originally, or it may have updated some quantities (we have not found this to have caused any issues for us), and it should also return the SO line quantity back under the reservation column.

That's it. Hope this helps someone. I use this process a lot for any shenanigans D365 throws at me with regard to production processes, depending on the error received, it has helped me with: validating a quality order, reporting a production order as finished, and pack slipping issues.

Report

Report All responses (

All responses ( Answers (

Answers (