Hi All,

We think we have the item cards set up correctly but when we process a Requisition worksheet or the Inventory Reorders report it doesn't prompt to order items.

To give a brief explanation, our BC is set up that we get Sales orders in and they will be send out immediately. So we don't order based on Sales orders but on Fixed re-order quantity.

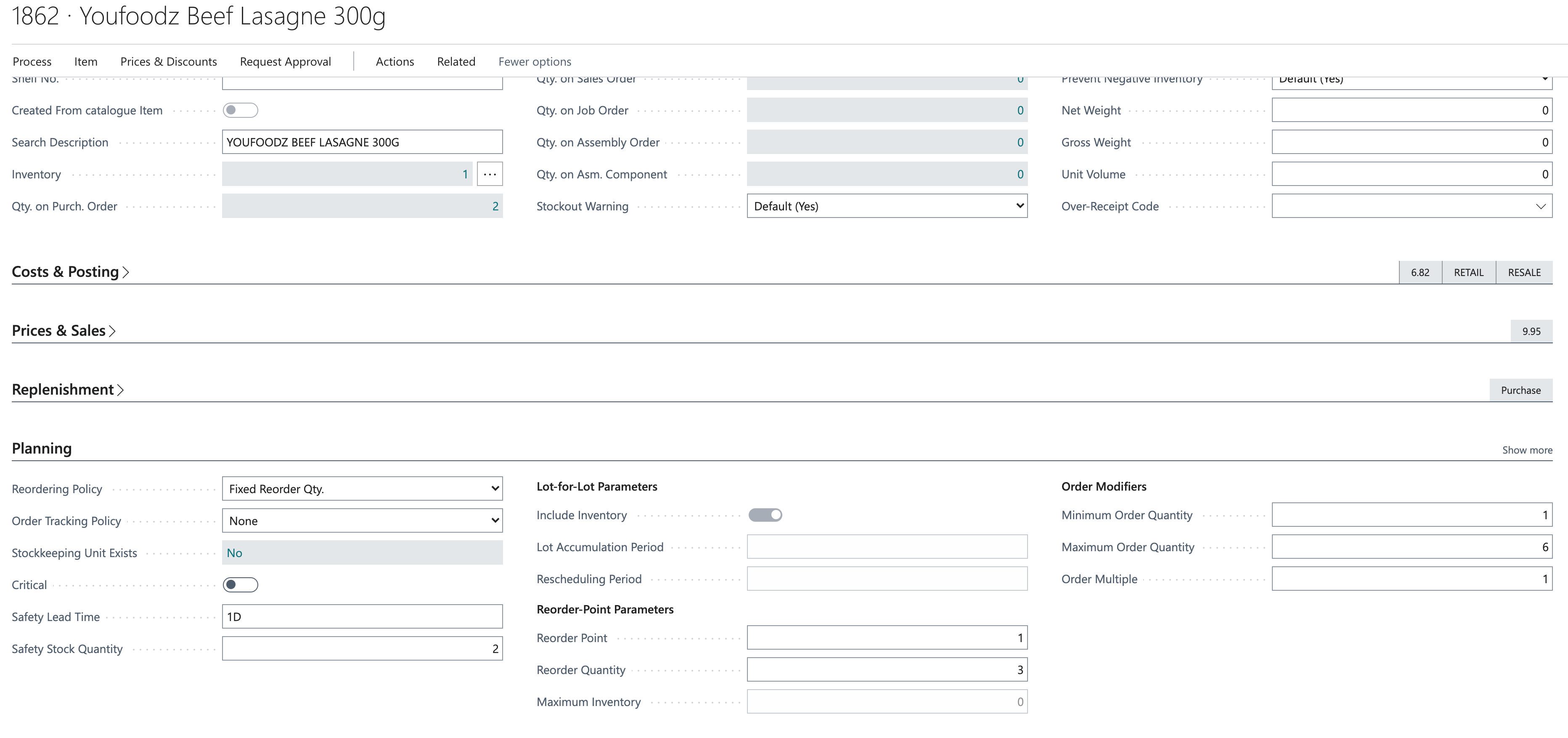

1. We set the item cards to Fixed Reorder Qty, we have 1 in inventory, and even a safety stock.

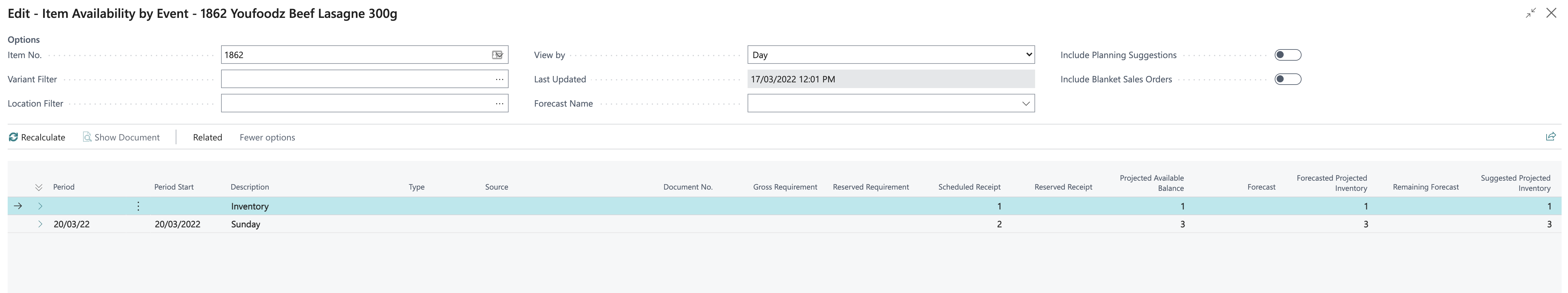

2. I'm unsure if we need Availability by Events by Location set up, so I'm including this screenshot just for reference:

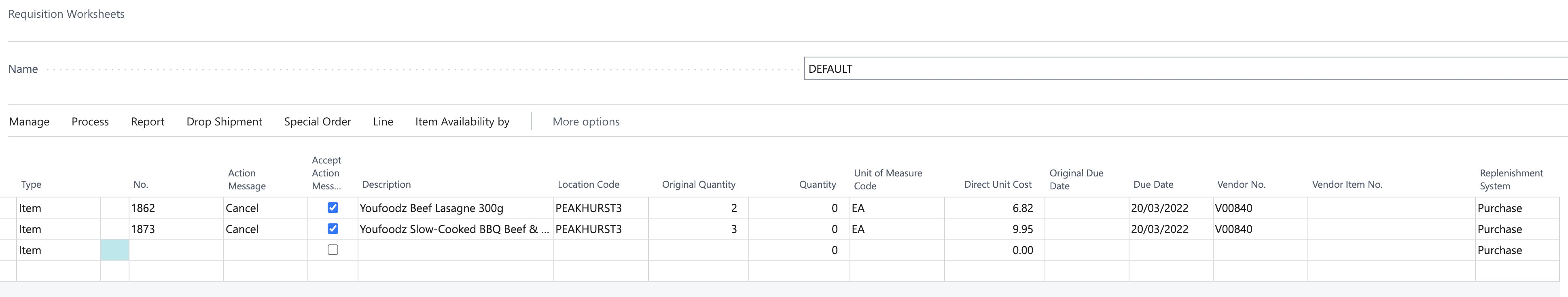

3. When we Go to Requisition Worksheet and calculate with any range of start and end date. It just doesn't show anything or in this case even says we need to cancel the PO (although we are out of stock of them)

4. If we run the Inventory Reorder report, it shows nothing at Qty to order.