Hi Experts,

I need guidance from you to achieve the scenario described below.

When ever a replenishment work is created for batch enabled products i need the system to Pick the batch based on the FEFO principle.

Scenario :-

Item Number - Product A -

Stored in Fixed location – PICK-1

Replenishment Trigger is set to fixed locations with Min- 15 and Max – 25

Bulk Locations are configured to allow mixed batches.

Location stocking Limit -

|

Location

|

Item Number

|

Unit

|

Quantity

|

|

PICK-1

|

PRODUCT-A

|

EA

|

25

|

Receipt of Product from 1st PO into the BULK locations

|

Location

|

Item Number

|

Batch Number

|

Expiry Date

|

Unit

|

Quantity

|

|

BULK-1

|

PRODUCT-A

|

BATCH-1

|

09/09/2022

|

EA

|

100

|

Now when I run the replenishment the system will create a Replenishment work to replen my pick location with 25 EA from the bulk locations

Stock status.

|

Location

|

Item Number

|

Batch Number

|

Expiry Date

|

Unit

|

Quantity

|

|

BULK-1

|

PRODUCT-A

|

BATCH-1

|

09/09/2022

|

EA

|

75

|

|

PICK-1

|

PRODUCT-A

|

BATCH-1

|

09/09/2022

|

EA

|

25

|

After doing sales for 15 qty. from my Pick location the stock status

|

Location

|

Item Number

|

Batch Number

|

Expiry Date

|

Unit

|

Quantity

|

|

BULK-1

|

PRODUCT-A

|

BATCH-1

|

09/09/2022

|

EA

|

75

|

|

PICK-1

|

PRODUCT-A

|

BATCH-1

|

09/09/2022

|

EA

|

10

|

Now I have another Receipt of Product from 2nd PO.

|

Location

|

Item Number

|

Batch Number

|

Expiry Date

|

Unit

|

Quantity

|

|

BULK-1

|

PRODUCT-A

|

BATCH-2

|

03/09/2020

|

EA

|

100

|

Stock Status

|

Location

|

Item Number

|

Batch Number

|

Expiry Date

|

Unit

|

Quantity

|

|

BULK-1

|

PRODUCT-A

|

BATCH-1

|

09/09/2022

|

EA

|

75

|

|

BULK-1

|

PRODUCT-A

|

BATCH-2

|

03/09/2020

|

EA

|

100

|

|

PICK-1

|

PRODUCT-A

|

BATCH-1

|

09/09/2022

|

EA

|

10

|

Now when I run the replen again the system creates a replenishment work to pick BATCH-1 and not BATCH-2 , which has a shorted expiry date.

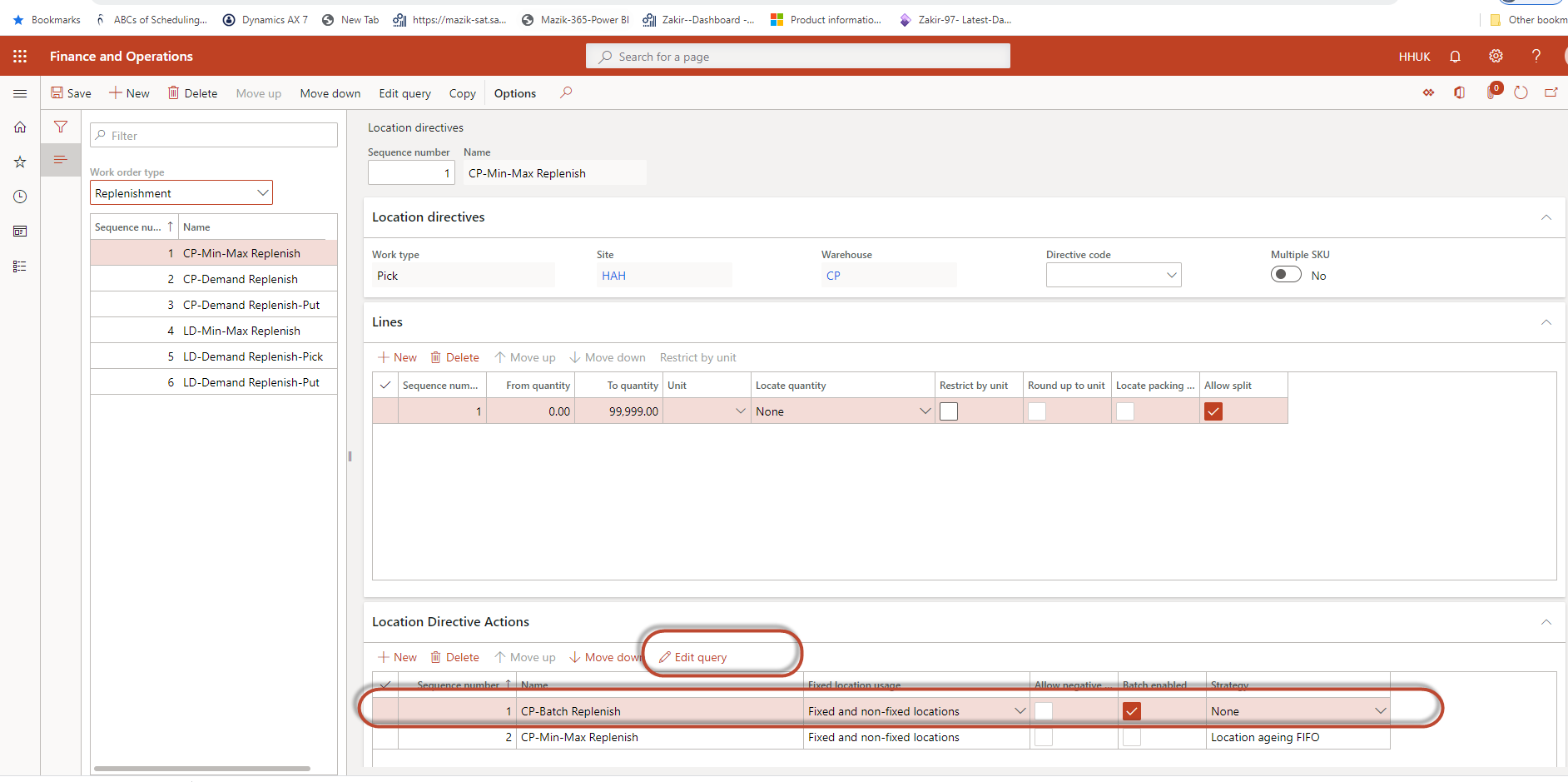

I have setup the location directive’s action query to sort by expiration date in ascending order.

Am i missing something here ?

we are on F&O -2020 release wave 1 - Platform - Update 34.