Hello together,

we have products that are bulk material and we store/ fill it in BigBags. Every BigBag stands on one pallet.

Unfortunately we do not have a process, that ensures that every BigBag has the same weight.

We fill the BigBags until they seem full to the warehouse worker (somwhere between 700 - 1100kg), than put it onto the scale and post the report as finished with the correct weight.

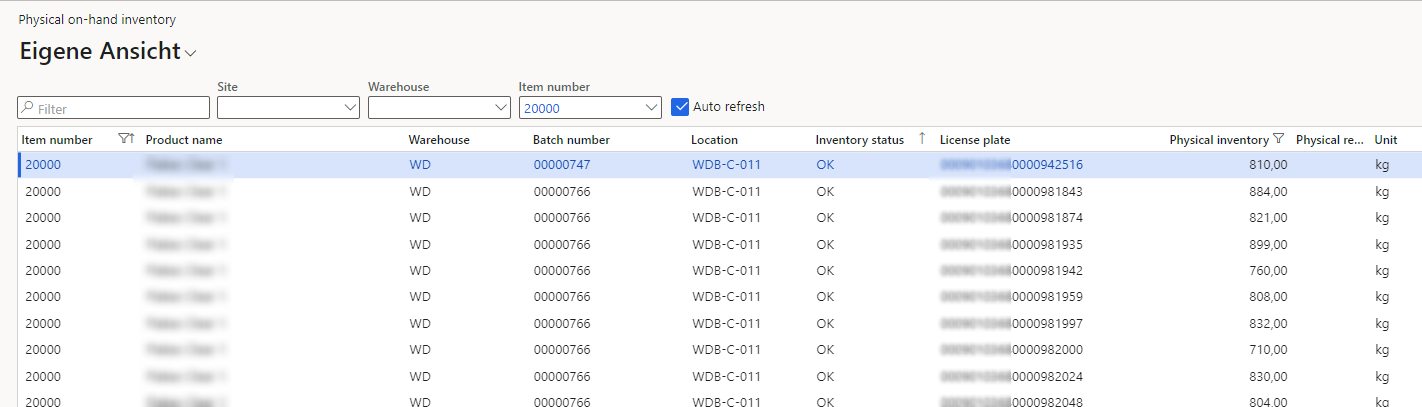

Therefore we made a setup, where every BigBag and its weight is unique identified by an own license plate.

Examples seen in the physical on-hand inventory picture below.

The problem is, most of our warehouse processes such as inbound and outbound are not based on kg but on amount of pallets.

For example:

For us it's only possible to store 8 pallets in one location - regardless of the weight of the BigBags.

We solved this by using the container type and the location stocking limits for container types, where we can define that the licenseplate is one container = "Pallet" and in the container stocking limits that 1 location = max 8 containers of "Pallet". This works fine for us.

But we have more or less the same issue for the outbound process.

We deliver mostly full trucks, which are limited to 20 pallets each.

As the inventory unit is kg and we are not able to define a unit conversion (it would be different for every BigBag), we have to define in the sales order the quantity in kg.

Anyway - I would like to tell the system in the sales order that I want to sell 20 pallets/BigBags (corresponds to 20 full license plates). Also the work should tell me to go to the warehouse and get 20 pallets/BigBags.

Is this somehow possible? As we are already using the container types on the inbound process, I was wondering if it's also applicable for the outbound.

I'm aware of the catch-weight functionality - basically it's exactly what I am searching for. Unfortunately we store the exact same prodcut also in real bulk storages (silos) and there is no solution for that in catch-weight.

Many thanks for the input

Jonas