We have a setup with wave replenishment from bulk locations to picking locations.

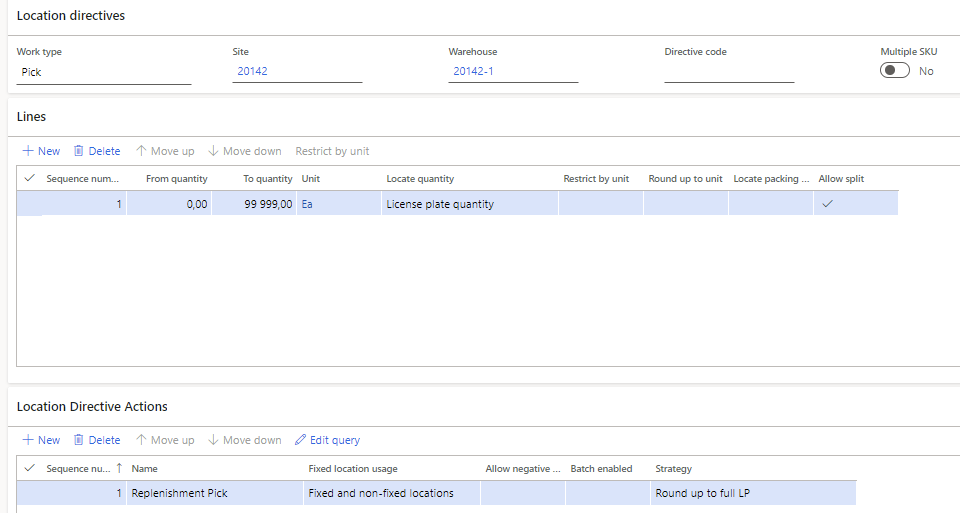

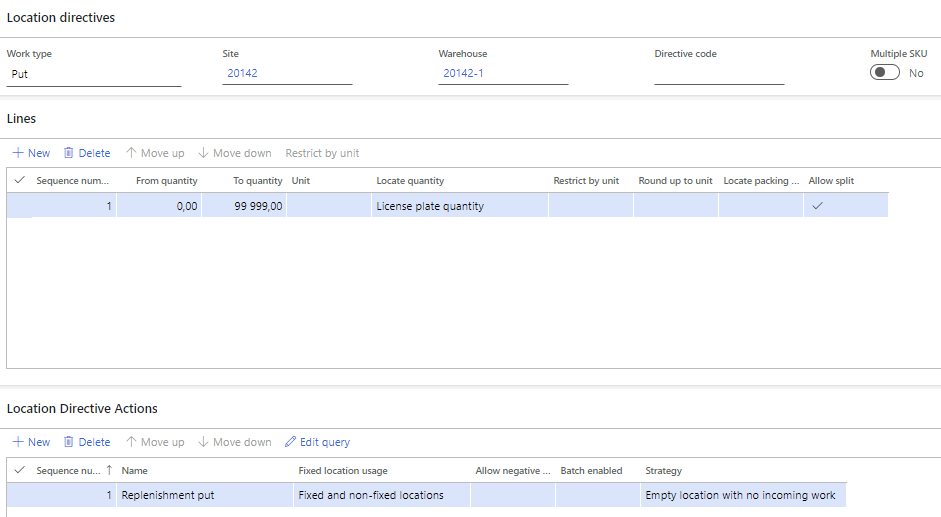

On the pick we have strategy "round up to full LP", and on put we have the strategy "emtpy location with no incoming work". Allow split on both places.

On both pick and bulk locations there is only room for one pallet. (This only concerns items which has no sticking limits yet)

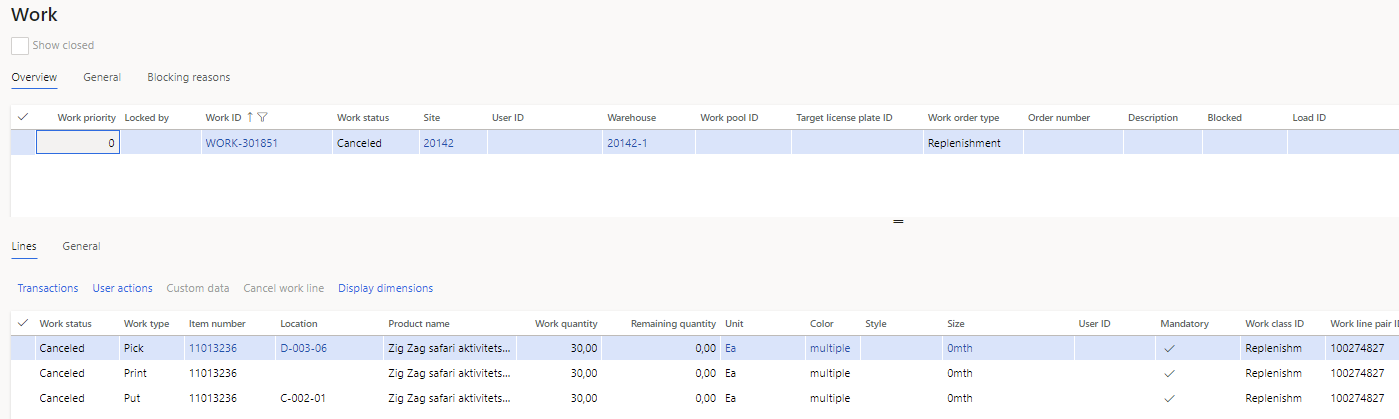

When the problem first started out, it genereted several picks and one put in the same replenish work. I adjusted the work template on replenishment so max picking line is set to 1.

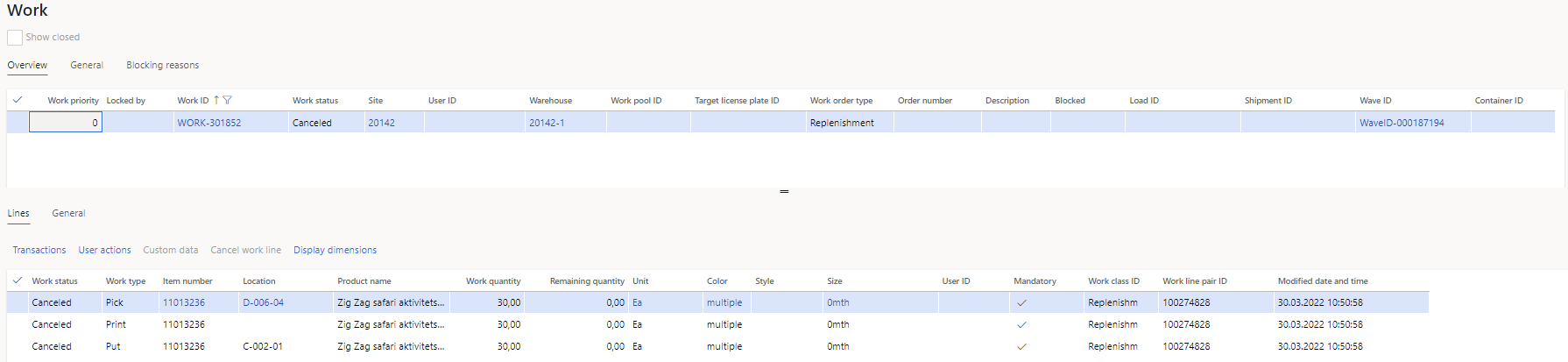

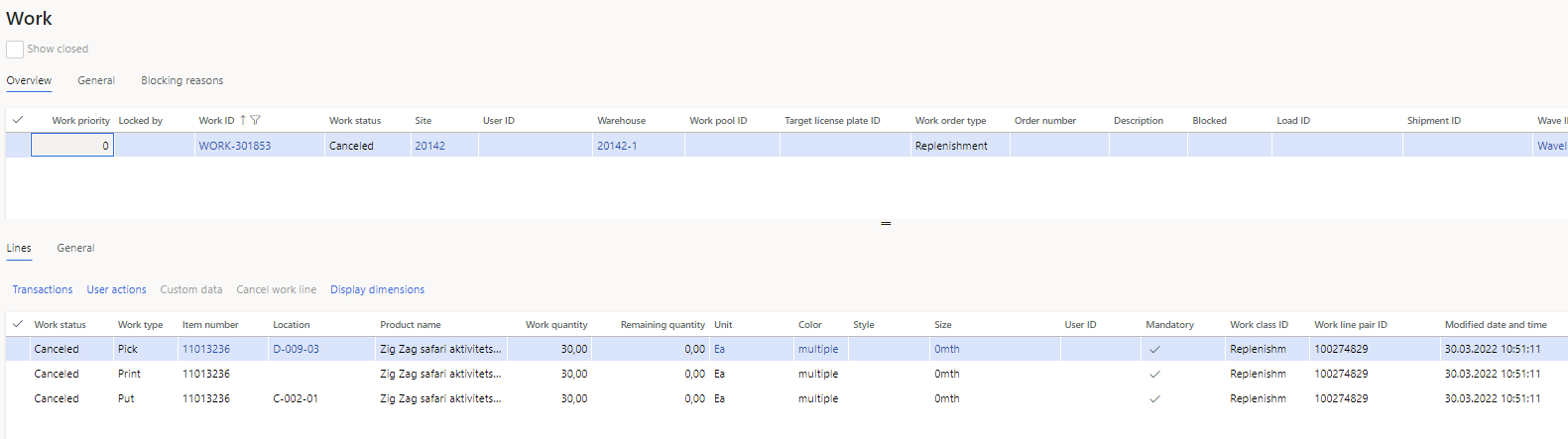

It helped in the way that is now generates new work for every line as intended, but all the replenish work with the same item gets the same put location on the replenish work.

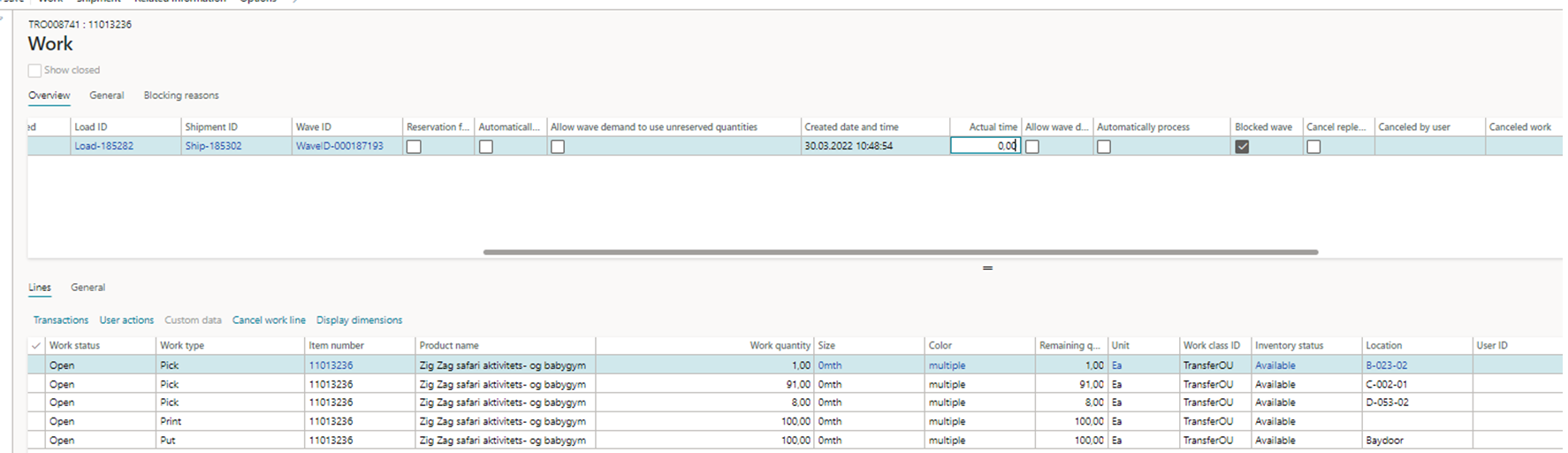

The problem occurs when we release orders and the system has to replenish from more than one location from bulk with the same item. On this example, the "original" work gives three locations for the item, but the replenish with three different works gives the same put destination. It looks like dynamics doesnt take into consideration the work than seconds before already has" taken" that empty location.

In this example all three replenish work gets c-002-01 as put location. But on the transfer order work, it shows that they are supposed to go to different (empty) locations. Just the way we want it to be.

Would appreciate any thoughts or insights