Hi All,

We are facing a scenario, where the Sales work is getting created for partial qty. The issue is caused by the stock not being in the appropriate Pick locations as defined in the Location directive.

We want to stock the entire work creation and the release process if such is the case. Is it possible ? How can we achieve this ?

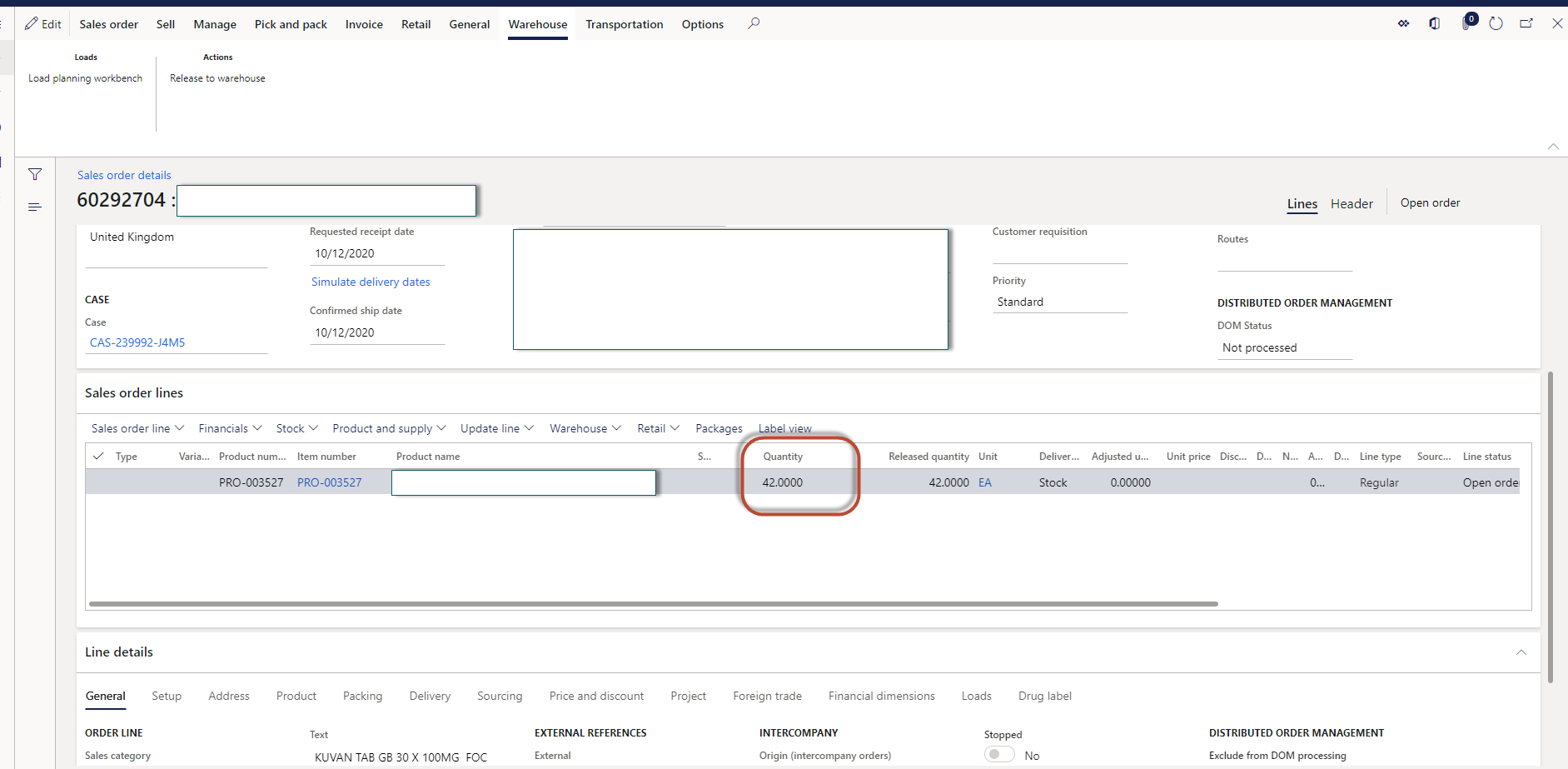

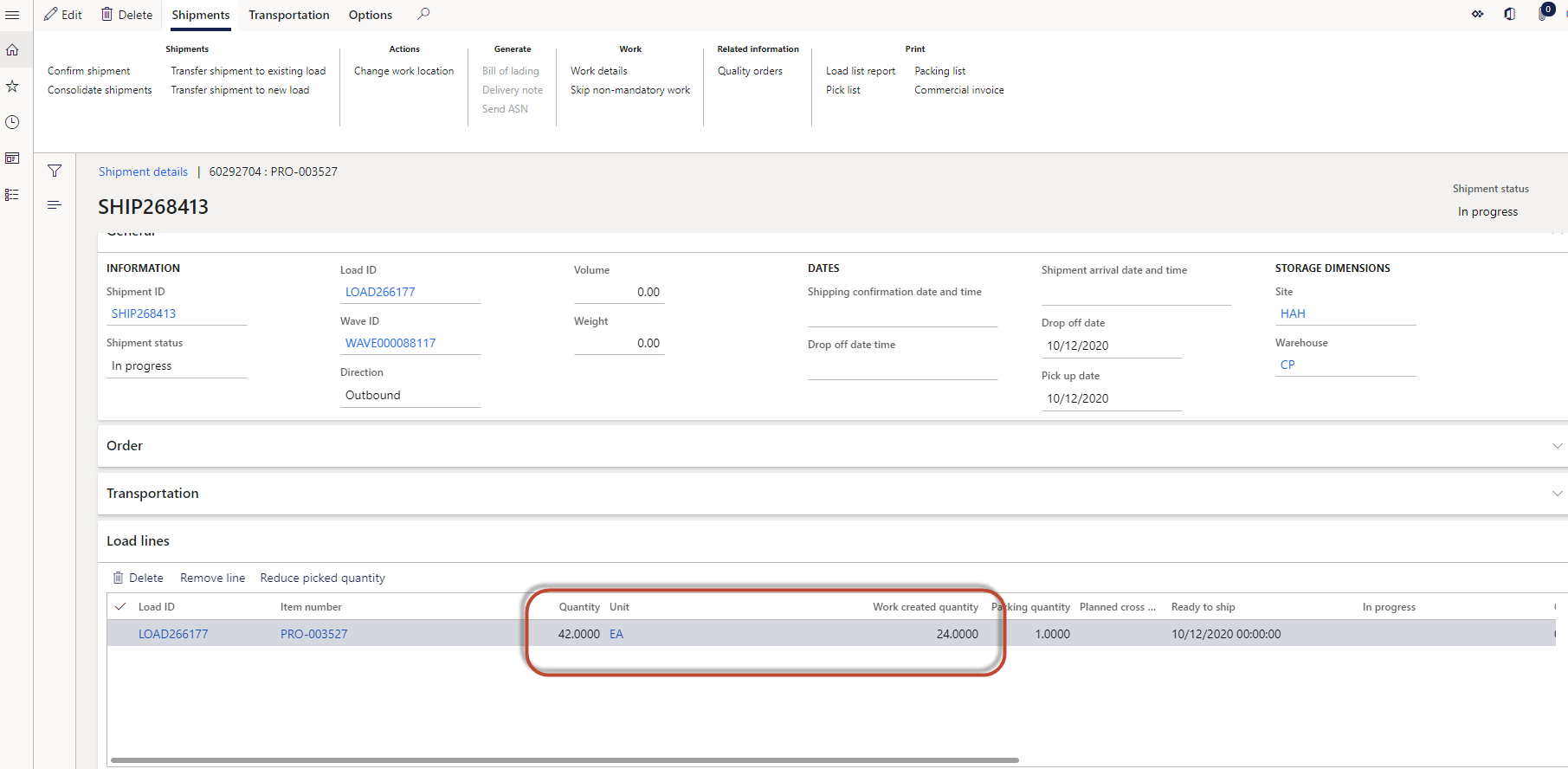

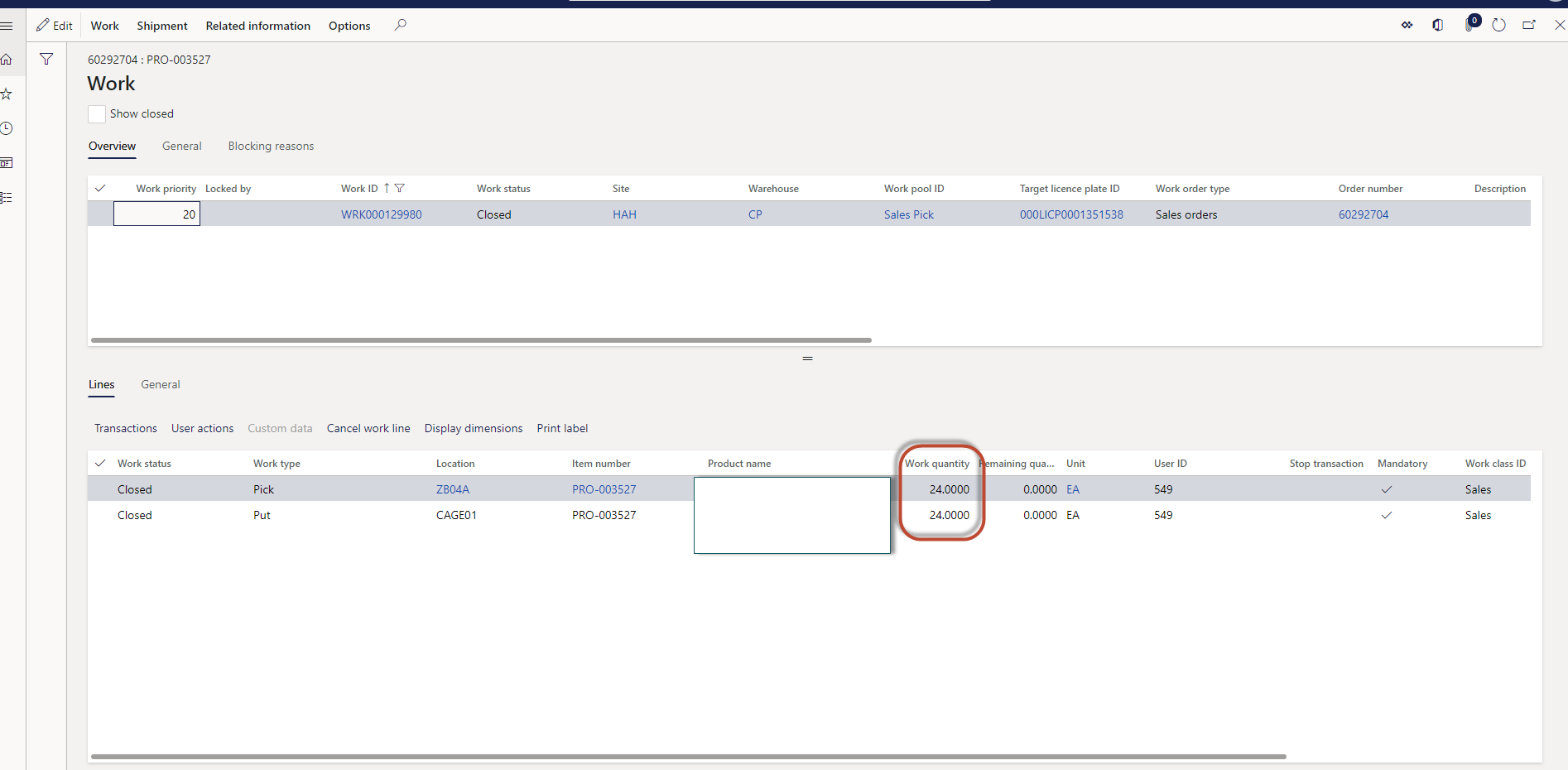

Example:- The SO Line qty is 42 EA. Out of 42 - 24 was in the Pick face and 18 was in GOODS IN location in physical available state. So when the reservation happened it reserved the entire qty.

The location directive for sales pick is defined to pick from only PICK FACE locations. So when the Release to warehouse happened, the system created work for the 24 qty in the pick face.

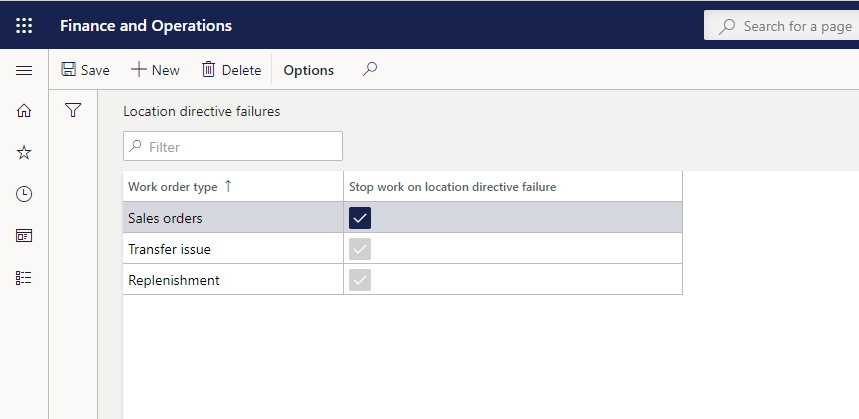

We want to STOP the work creation and roll back the release process in such cases. Is this possible ?

The location directive failure is also set for Sales orders