Hi everyone,

I'm turning to you as I struggle with the multiple sourcing for my component.

Context :

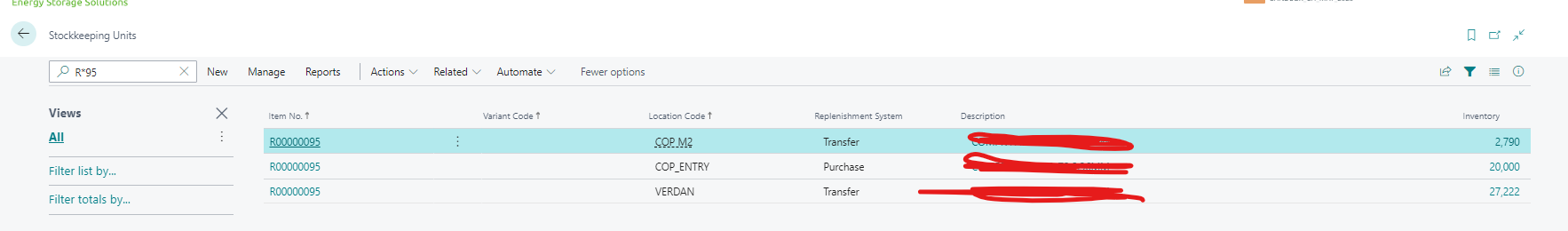

Company has an inbound area (COP_ENTRY) + an external warehouse (VERDAN) and a production line (COP_M2)

Components may go directly on the production lines from COP_ENTRY to COP_M2, or may be stored at VERDAN then used later on COP_M2.

It looks like that

The main flow is functional, meaning that our SKUs are setup in a proper way and the MRP is running properly.

Firm prod order.

But, where I need your assistance is to create the alternative flow, i.e. COP_ENTRY to COP_M2, bypassing VERDAN.

I tried to create a new SKU with this but of course it gives me an error, as there is already a sourcing.

I guess it has to do with the Variant field, but I'm kinda lost here and would need your help.

Wishing you a nice day and looking forward to hearing from you