Good Morning All,

We have been working with a company in the UK on our deployment. Planning seems to be a huge wall for us as a company.

Our sales orders are for 1 to 1000 units, some could be multiples of the same or could all be one offs running around 300-400 sales orders across 30 projects at any one time.

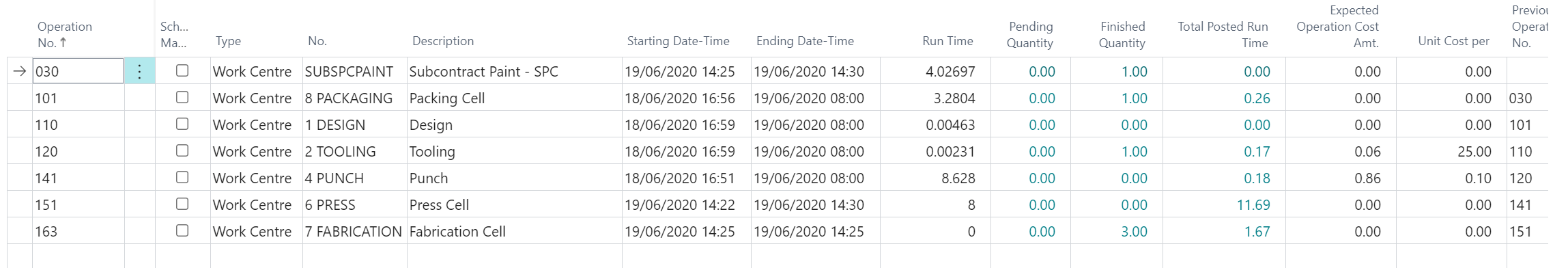

Our routings are few steps ie 5 steps but the timings per item are short - 3 to 15 minutes per routing step per item.

As our manufacturing is fluid in line with customers changing needs, we have to replan and reschedule a lot and during this time, we could have a job of 500 items, 50 of which are left to design, 100 of which are left to cut, 200 of which are ready to ship to a subcon painting process and with 50 already at the paint plant and 100 delivered to site. Typically, we dont finish a full routing on all items before the next stage is started, and we will often cut work to be fabricated first.

If we change a date or time in one of the above routing lines, the others update automatically.

Scheduling wise, we have explored with the current partner and scheduling companies options here around visibility and flexibility. BC wants us to set rules in the system for it to follow such as a 48 hour gap between each stage and use that, but after 2 years of struggling on, not being able to scheudule, unless there is a way that the partners and we havent through it, i think we need to see about rough cut planning.

Ideally we want to system to manage it all but as a fall back position, we would like to set the routing start date for the released production order, i.e. Design to start on Monday 27th June and the system plan the released order end date, we then want to set the tooling date for Thursday 30th June, then punch Monday 4th July etc etc. We are told the only way to do this is to turn planning off but the partner have never done this before and not sure of the impact.

We arent BC experts, as end users we just want the system to plan as per its own rules but then where needed, we want to override it on a released production order by released production order basis to set the start dates we know are going to happen and for us to keep a view on the capacity load on the work centres to ensure we are managing them well and if overtime is needed, its justified.

Has anyone out there had similar issues and have any solutions - its the one last area of the system deployment we are really struggling with.

So in short, we want / need to be able to update dates at released production order level (not at item level) and for the system not to overwrite what has literally just been done.

I hope ive explained that well enough, if not, please ask for more information