I defined a new item finished good and 2 raw materials 001 and 002

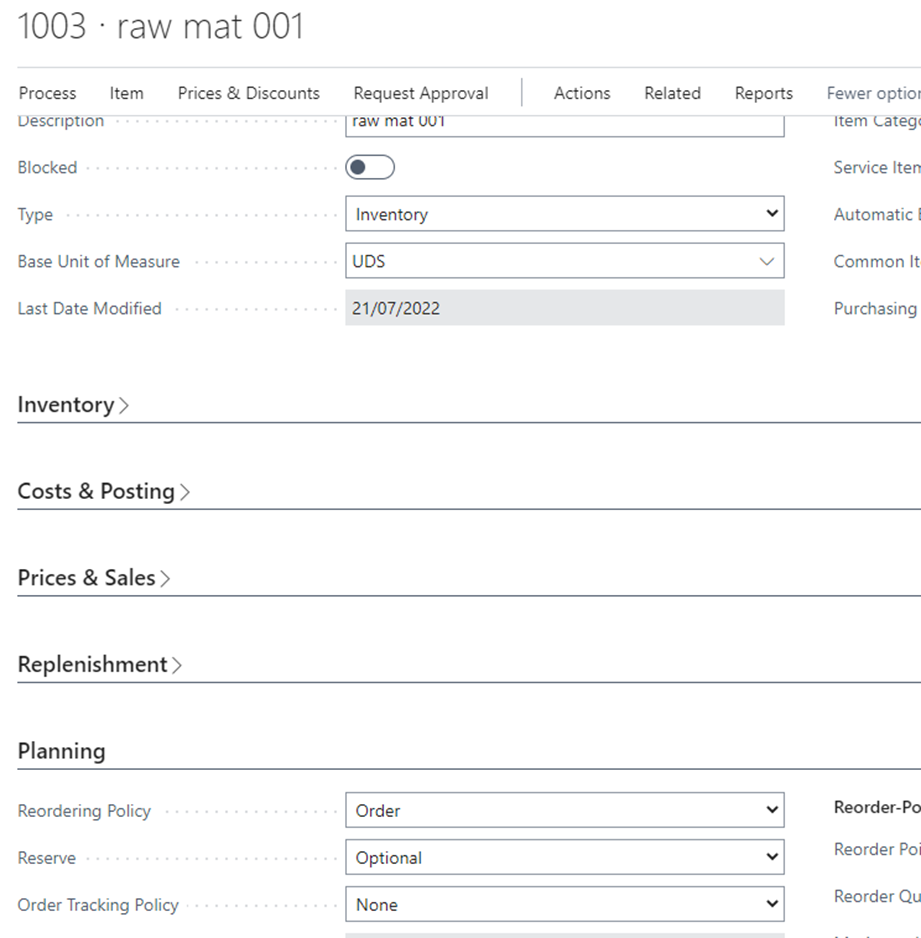

The 3 of them are defined as

The reordering policy for all of them is order

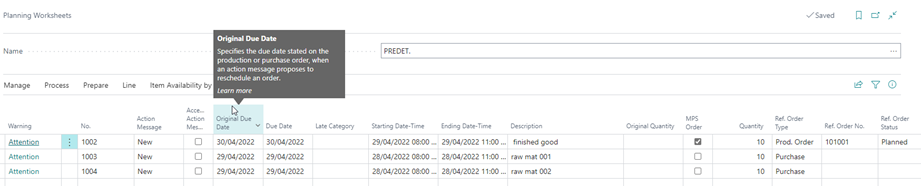

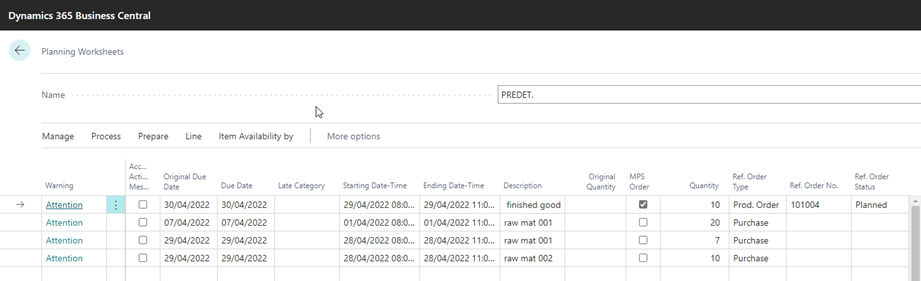

I create a sales order , release the order

And run the planning worksheet

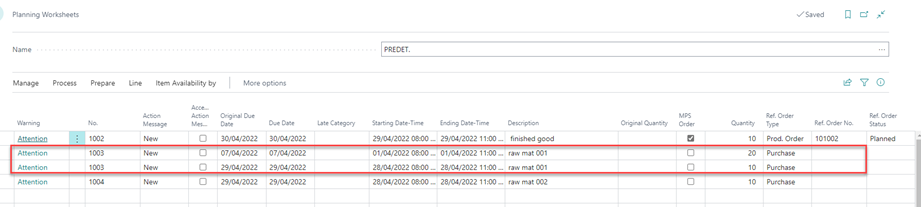

Lets change a little the raw material 001 and put the reorder policy to max and define some max

Re run the plan wkst with empty warehouse

Its enough intelligent to ask for my max + the to be used quantity

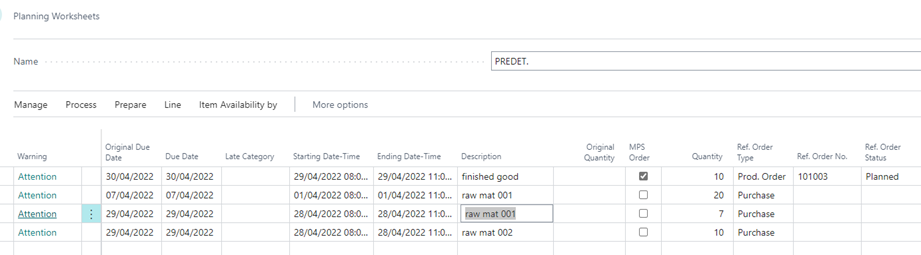

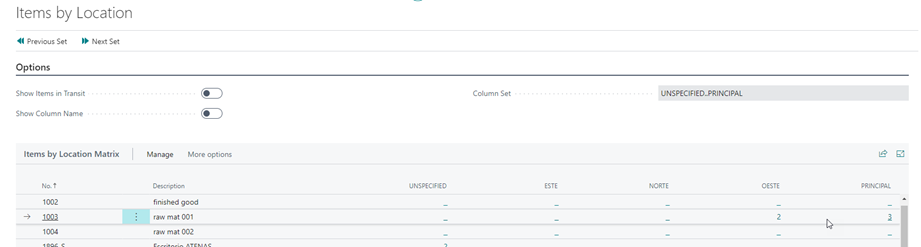

Now, let’s put some inventory for 001, 3 items to be sure, and

Now im going to add 2 more in another location

Got the same result

Why this? Because I need to define in which location is the raw materials and where is the finish good, also, the transfer routes to make the system calculates the transfer order.

I used Order as reorder system because I don’t need to produce anything until I have a sales order, in the same idea, the raw mats can be ordered in the first example or planned in the second (max qty).

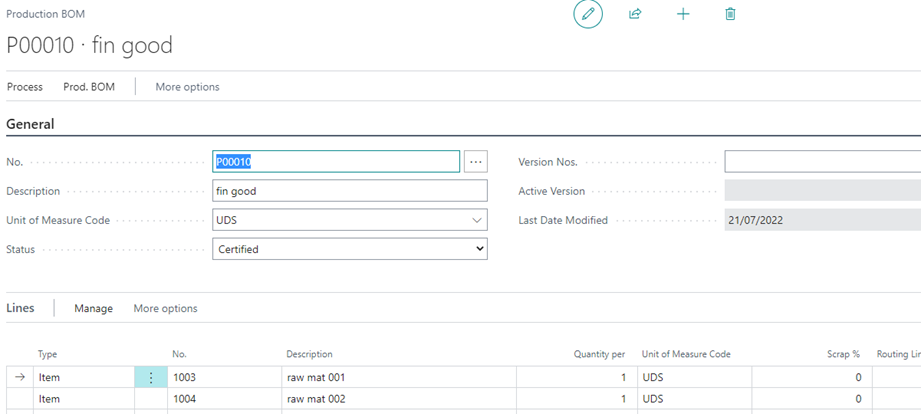

My BOM is this one

And I not using routing, std warehouse, no pick or put away and the planning worksheet is the standard too.

For the item replenishment

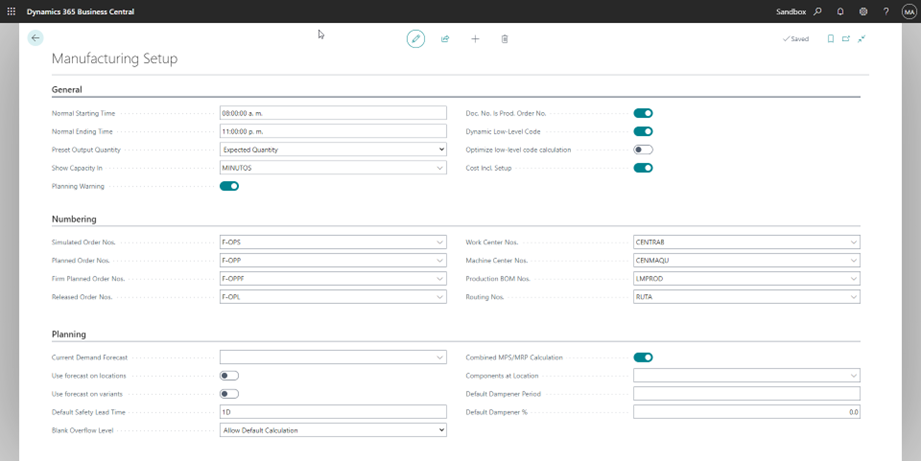

And finally, my manufacturing setup

Hope that helps