Hello!

Good if someone can confirm or give me a hint here.

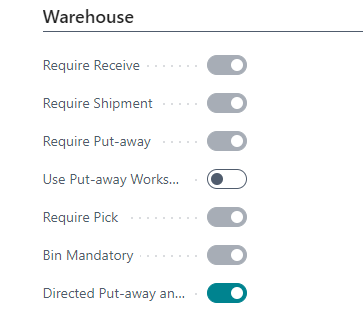

I have a customer running on BCO and a warehouse setup with directed put-away and pick:

The logic in Movement worksheet when suggesting movement is always to try to get the movement done as little movements as possible, leaving a lot of bins low on stock so the suggestion from the system is to create movement from bins with the highest stock-level.

The suggestion from the customer is to always go for the bins low on stock in order to empty all the bins low on stock.

For example:

100 qty is to be moved from Buffer-zone to Picke Zone.

We have 50 qty on Bin: B10

We have 150 qty on Bin: B12

The system will suggest a movement from Bin B12.

My client would like the system to start with the 50 QTY from B10 and then 50 QTY from B12.

Is there a way to solve this OR do you have any suggestions on haveing a workaround-process taking care of the bins low on stock and how to set it up?

#warehouse

Report

Report All responses (

All responses ( Answers (

Answers (