Hi,

I don't think there is a exact or perfectly simple way to achieve this, I'm not a developer nor a logistics expert but here is what I would try to do in your situation.

Goal: Get the +-3000 items that have quantities in location 'Blank' to a new location "Main" by using the Item Reclassification Journal.

- Create new location called e.g. "Main".

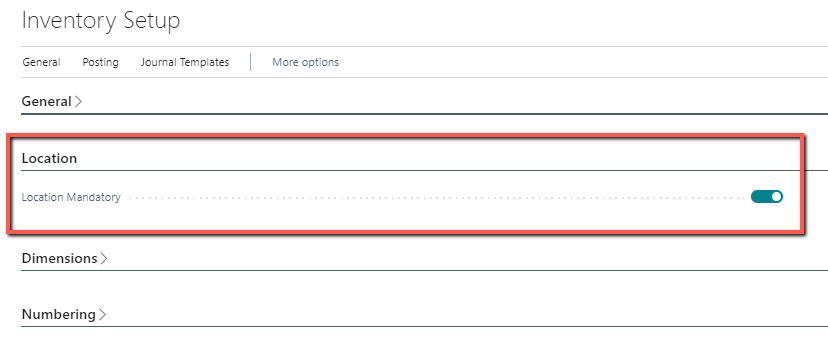

- Define the setting "Location Mandatory" in Inventory Setup to true. Preventing any further transactions to the 'blank' location.

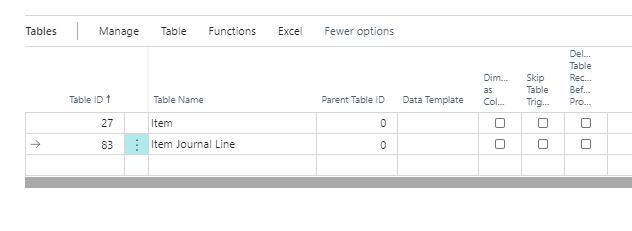

- Create a Configuration Package containing:

- Item table 27 (delimit included fields to required fields, also reduces size of excel sheet, else every field from item table is included).

- Item Journal Line Table 83 (delimit included fields to required fields, also reduces size of excel sheet, else every field from journal table is included. Try include only what you need as displayed in BC. Note the template and batch name for where to import to e.g. Template = Transfer, Batch = Default).

- Export Configuration package containing the 2 tables to Excel.

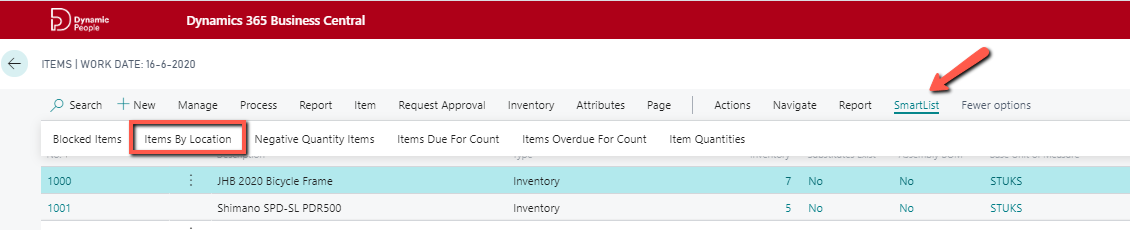

- Run the SmartList found in the Items List Page called "Items By Location"

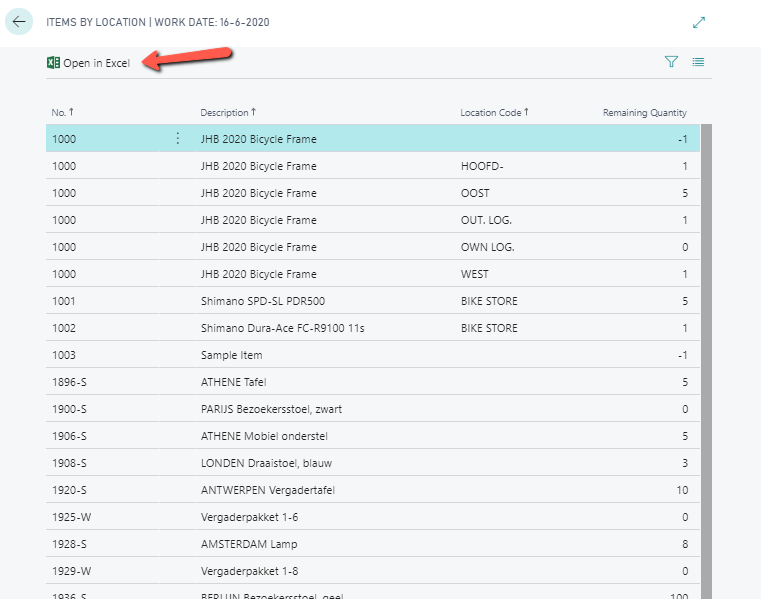

- Populate the Configuration package for item journal line using the items to be transferred and the remaining quantities to be transferred from the SmartList.

- Import configuration package and apply only table 83.

Desired result: Item Reclassification Journal batch 'Default' is populated with the +-3000 items with Location Code = 'blank', New Location Code = 'Main' and Quantity = the remaining quantity that is in location 'blank'.

Note: This process will only result in the quantity of items in location 'blank' to be 0, any item ledger entries that were posted where location was 'blank' will remain and only future transactions will be done in new 'Main' location.

Of course this is just an idea and hope it gives you some ideas and perhaps help you along

Let us know how you get along.

Regards,

Martin