Hello All,

I have a scenario for Manual Packing to identify Pcs Pack and Standard Box Pack.

Scenario Pre-Setup

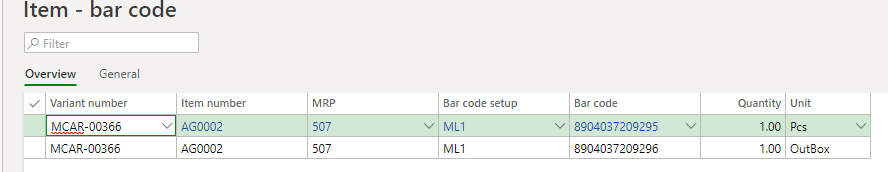

1. I have Setup Barcode for Item, here i have 2 a. for Pcs b. for Box

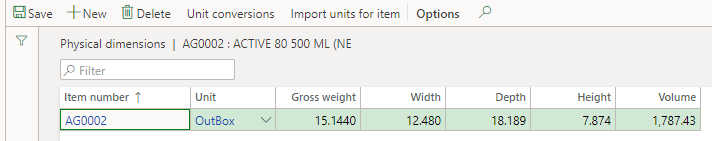

2. Physical Dimension for Box Unit and Pcs

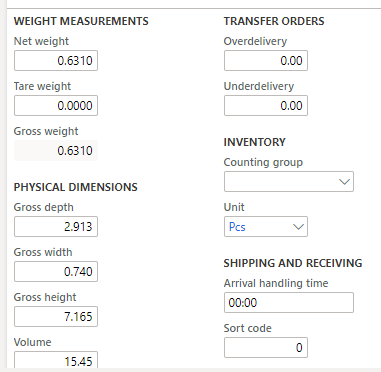

3. Now If i have a sales order of 50 Pcs, the work created for Pick is split into Box and Pcs requirement

Problem-1, the put is done only in pcs, though i have setup location directive lines unit wise same as pick. Even if this is to work this way "Ok"

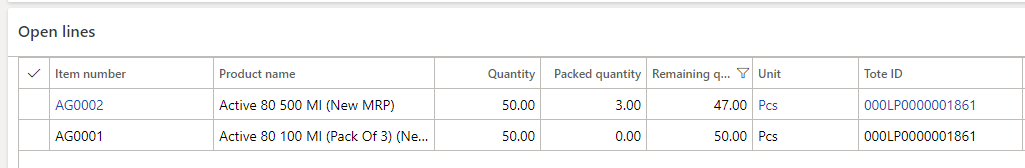

4. Now on the manual pack user can see item lines in Pcs i.e. 50 Pcs

5. I am creating a New Container

Actual Result

1. while i scan the OutBox unit EAN code, system calculates only 1 Pcs

Expected Result

1. System should identify it as 1 OutBox or 24 Pcs as per unit conversion

2. With the above Work ID reference, Packer should get list as per unit i.e. 2 Line Item of Pcs to be packed and 2 OutBox to be packed (for which essentially to packing box is used, but a container ID generated)

Just to add further, one may ask why have the OutBox on packing station and not rather directly move to Baydoor.. Here, its essential for me to know how many containers i have on Shipment which includes Manually packed container and Standard container box. As i need to generate Label for each box.

Is it right process or something else can be done.

Looking forward to your inputs and suggestion

Regards,