Capacity Planning in NAV/D365 BC – Part 2

CDsilva

CDsilva

Welcome to Part 2. If you’ve missed part 1 please follow this link

Brief Overview:

We covered two key aspects in part 1 and this blog covers another two key aspects of capacity planning

- Routing

- Production order

Setup:

Routing –

- In simple terms, Routing is a recipe for the Production BOM.

- The routing is the basis of process scheduling, capacity scheduling, scheduled assignment of material needs, and manufacturing documents

- Once a production order is created for that item, its routing will govern the scheduling of operations.

- The routing decides which work centre will be worked first or second or in parallel.

To create a routing for an Item,

- On your search bar type Routing and click on new.

- Enter the No. same as your Item No. and description

- Type= Serial, if you would like all routing lines (work centre/machine centre) to process serially based on the operation no.

- Type= Parallel, Select Parallel to calculate the operations according to the value in the Next Operation No. field.

5. Under the lines, enter the operation No, select type as work centre/machine centre

- Setup time– The time taken to set up the work centre for each production order.

- Setup time Unit of Measure– Unit of measure is Day, hours, minutes.

- Run Time – The time taken to produce one item or product.

- Run time Unit of Measure– Unit of measure is Day, hours, minutes.

- Wait Time – The waiting period before you begin the next process or operation.

- Wait time Unit of Measure– Unit of measure is Day, hours, minutes.

- Move Time – The time taken to move from one work centre/machine centre to another in the routing.

- Move time Unit of Measure– Unit of measure is Day, hours, minutes.

- Fixed Scrap Quantity– Please enter the fixed scrap quantity if you have a definite figure

- Scrap Factor % – Define the percentage of scrap generated while creating a finished item.

- Note- You can skip the scrap on the routing and add it as a whole percentage on the Item card.

- Concurrent capacity– count of machines or resources working simultaneously at one operation.

- Send Ahead Quantity – This is mostly used in parallel operations where a portion of a lot is send to next operation before the current operation is completed.

Production order

- Production orders can be either created manually or created from MPS/MRP Process from the planning worksheet.

- Production order allocates the load on the work centre/machine centre.

- Once a production order has been created and scheduled, it has to be released to the shop floor to be executed. During execution of the order, you record:

- Materials picked or consumed

- How much time was spent working on the order

- Quantity of the parent item produced

Learn more about production orders from this link

In my example, I’ll be creating a released production order for the Item M4*

- To create a Released Prod. order, type Released Production orders in your search bar and click on New.

- Enter the Source No. as your Item No and add Quantity.

- Add your global dimensions if you have set it up. and click on Refresh Production order

Allocated quantity

- Navigate to the work centre to understand the allocated quantity and load

- Once production order is created, depending on the due date of the production order, NAV decides the start and end dates then it allocates the work centre for those dates.

- Click on Load on the work centre

Key points

- If the work centre/machine centre is completely allocated then load is 100.

- Load is not allocated on a non-working day including weekends and calendar holidays.

- NAV allows over allocating the work centres i.e. if we have multiple production order with close proximity of due dates, NAV will over allocate the qty on the work centre load.

- User will have to manually change the due date or re-plan the production order.

- You can change the view by filter from Day, weeks, month, quarter, year and period based on your requirement.

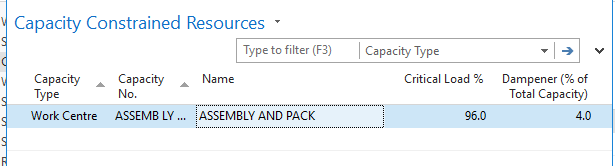

Capacity-Constrained Resources -Its a setup that avoids overload of specific resources and ensure that no capacity is left unallocated if it could increase the turn-around time of a production order.

Here, you can assign a critical load % and dampener(% of total capacity) to a work or machine centre.

Critical load %– It’s a maximum percentage of load you can assign to a work centre.

Suppose you have a work centre for melting a metal and you can only assign 80% load to it. You can easily assign critical load % to the work centre in the capacity constrained resources.

Dampener – Its the percentage of load which is allowed to reschedule or re-plan for the next day.

On the search bar, type capacity constrained resources, click on new to add the constraint

Posting a Production order

I’ll be going through a simple production journal posting to showcase the impact on the capacity ledgers.

- Open your released production order click on the line and select the production journal

- Below is my production journal, where my production order consumes two raw materials to produce 30 parts of the output item.

- The three output lines doesn’t mean we would be generating 90 output items, it’s only to showcase that the 30 items will be machined first then will be assembled and packed. The output still remains 30.

- Enter the setup time and Run time manually. Note that only setup time and run time is used for cost calculations.

- Click on post to post the production journal.

Capacity Ledger entry

Once the production order is posted, navigate to the work centre and click on capacity ledger entry

Click on your first work centre, click on capacity Ledger Entries and observe the below result.

That’s the end of part 2. Thanks for reading!

Next blog: Cost calculations in capacity planning.

This was originally posted here.

Like

Like Report

Report

*This post is locked for comments