Hi,

We are running AX 2012 R3 and we have some problems with our planned purchase orders. We think we are sometimes indicated to purchase too early than needed.

Since we started using the system we have seen our inventory levels on purchased items (components) increasing. We have noticed many examples where the planned purchase orders from the nightly MRP run are far from optimized.

Just for information I want to mention that the demand on components are coming from demand forecast of the top level products which are exploded downwards. Some of our purchased components have a long lead time which makes us placing the orders quite early compared to when the component is needed in production.

The work process for purchasing is that our planners / purchasers are looking at the planned order list and are handling orders where order date equals todays date.

Unfortuently we find planned purchase orders that we need to handle today that are completely unnecessary.

Example.

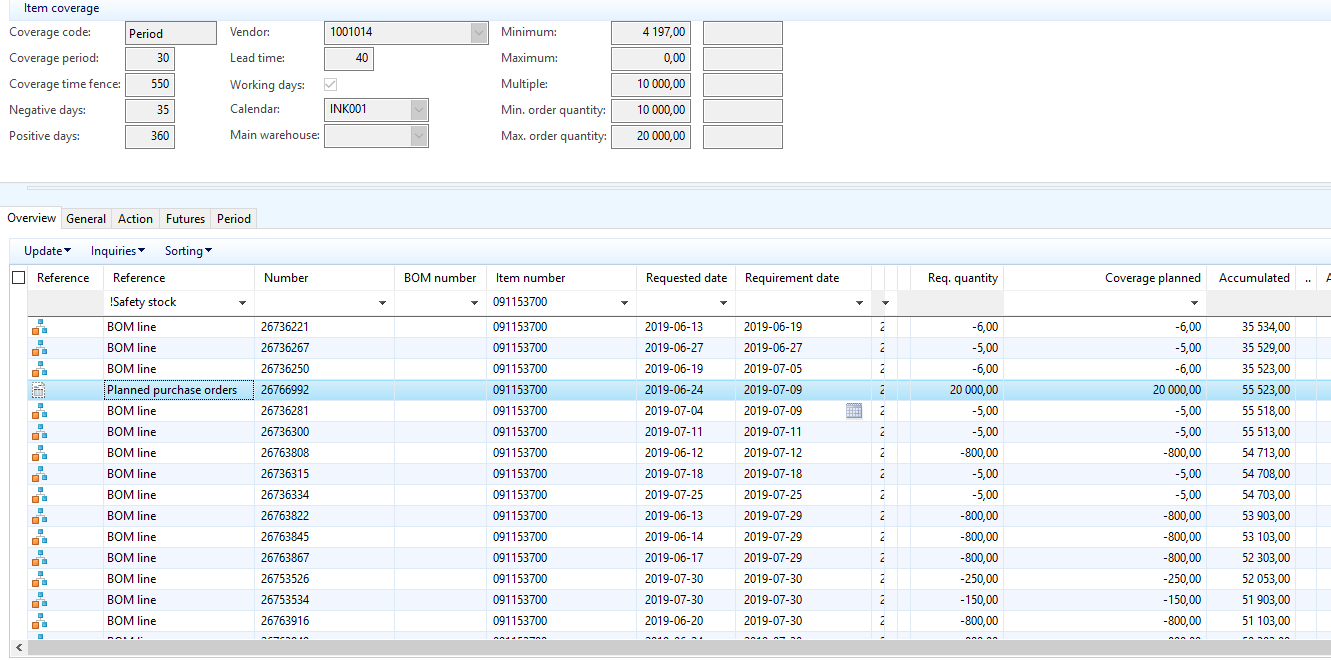

The screen shot contain a planned purchase order where the order date equals todays date (2019-05-08).

If the planner just firm the order we will end up with 55 523 pieces 2019-07-09.

It is not necessary to send the purchase order today since it will result in a too high stock level compared to what we need.

I think I found out why this happened. If I look at the pegging of the planned purchase order I will see that many of the BOM lines had a requested date near 2019-07-09. The requirement dates of the BOM lines were in most much later then the requested dates.

We are running our production with finite capacity on some resources. My theory is that during the MRP run the BOM lines were first needed in July, but then moved by future messages into the future. The conclusion is that the BOM lines got new requirement date but the planned purchase order is still on the same place as it was from the beginning.

Temporary solution

If I do a full regeneration of the net requirements on item level, I will end up with a much more optimized plan. So generating the net requirements of the single item is giving me a better situation.

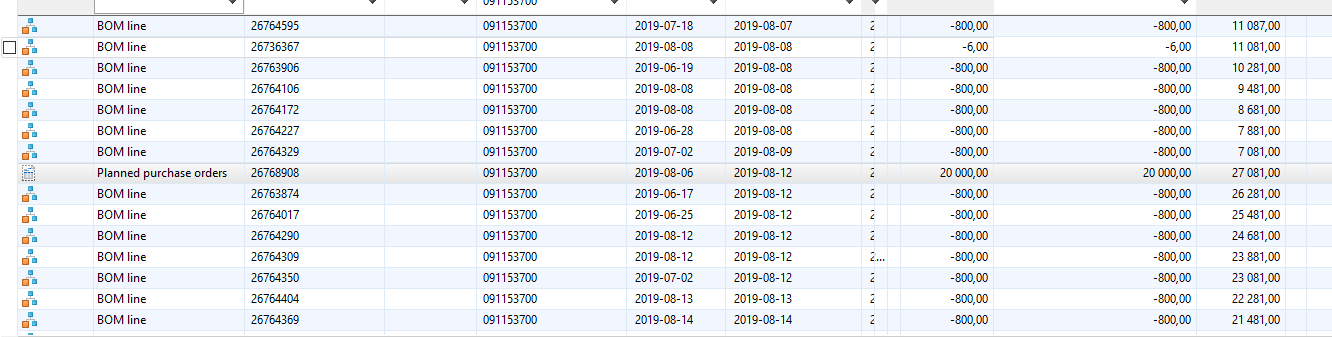

After regeneration, I will find the first planned purchase order one month later than in the first screen shot of the net requirements. The first planned order now has an order date of 2019-06-11 and is needed first in the middle of August. The on hand quantities are also on a better level than in the first version.

With this result, we would avoid purchasing too early.

But there must be a way to make AX generate this kind of optimized plan during the nightly MRP?

We can’t be dependent of the planner / purchaser looking at the requirement profile of each purchased item and doing an manual investigation if to purchase the item. It is also time consuming to do manual regenerations of the net requirements.

Someone with knowledge or experience about situations like these, please reply.