Hi Ludwig

Thanks for your reply

QC refers to Quality Check

Process :

if we have Work order of 100 pcs , 80 is good pipe and 20 is bad pipe from QC rejection .

We book 80 pipe through START and Report as finished , which will consume Picking list , Route , and Finished goods .

20 We book through manual Picking list called QC Rej. Picking list contains the Raw material for 20 pipes and 20 to be crushed item.

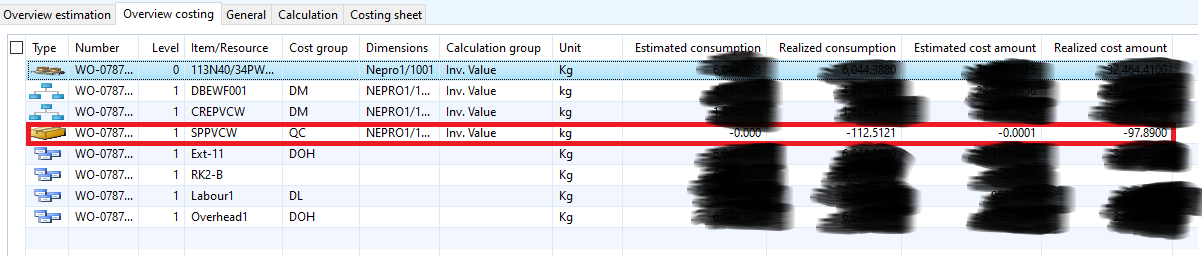

We have in BOM added to be crushed item (SP*).In BOM for this to be crushed item we mention Quantity (-0.00001) Per Series 10000.

for 80 finished good pipes when we post route the machine depriciation cost , direct overhead , labour cost is booked

for 20 QC rejection i,e to be crushed item the machine depriciation cost , direct overhead , labour cost is not booked .

We want to book machine depriciation cost , direct overhead , labour cost for this 20 QC rejection , i,e to be crushed item .

in the below example we want to book machine depriciation cost , direct overhead , labour cost for the production of sppvcw item