Hello,

I am trying to set coverage groups and generate net requirement for a product, but results, which I am getting from MinMax coverage code Master Planning are different from what I do expect from MinMax. Maybe I am wrong about this!

I set Min to 1250,00 and Max to 1500,00. If I am correct, I should receive planned purchase order when invent on-hand goes below 1250,00. Default order settings are empty.

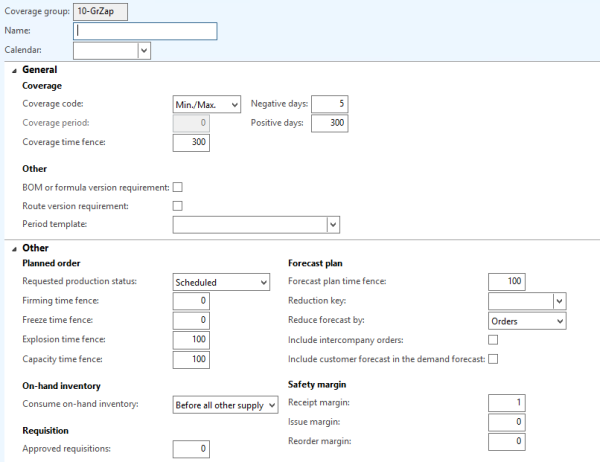

Coverage group settings:

Master planning settings:

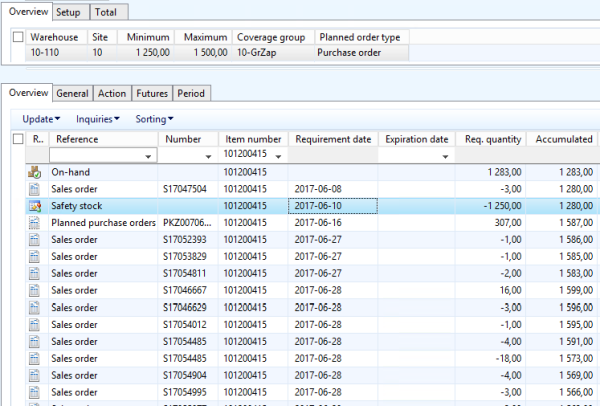

The result of master planning (session date is set 2017-06-10):

Do I interpret these results correctly and this one is wrong? We are getting planned purchase order for today when invent on-hand is at 1283,00 (min is 1250,00). If I select "On-hand" ReqTrans and look at "Pegging", it is consumed by all sales orders, but not by safety stock.

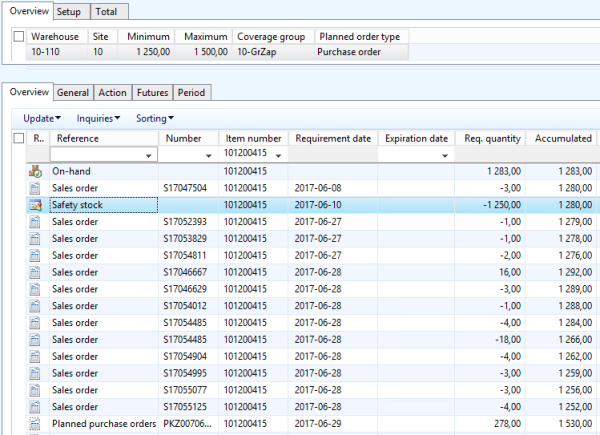

I took a look at code and it is determined by "Priority" at ReqTrans and it is set based on InventTrans IssueStatus. Safety stock has no InventTrans, so it is set to 0 and it results that it is last position in "Pegging". If I make a small change and set priority for safety stock, this is what I will get:

Safety stock requirement date is today's date and it is fully covered by invent on-hand. When it goes below 1250,00 (min) on 2017-06-29, planned purchase order is already scheduled for this day.

Can somebody explain, which version is correct? Is there any parameter for this (did not find anything in code)? Am I wrong about MinMax replenishment model? Is there a bug in Microsoft Dynamics AX2012?

I experienced the same problem with MinMax in Microsoft Dynamics 365.

Thank you for your opinion!