Hi community,

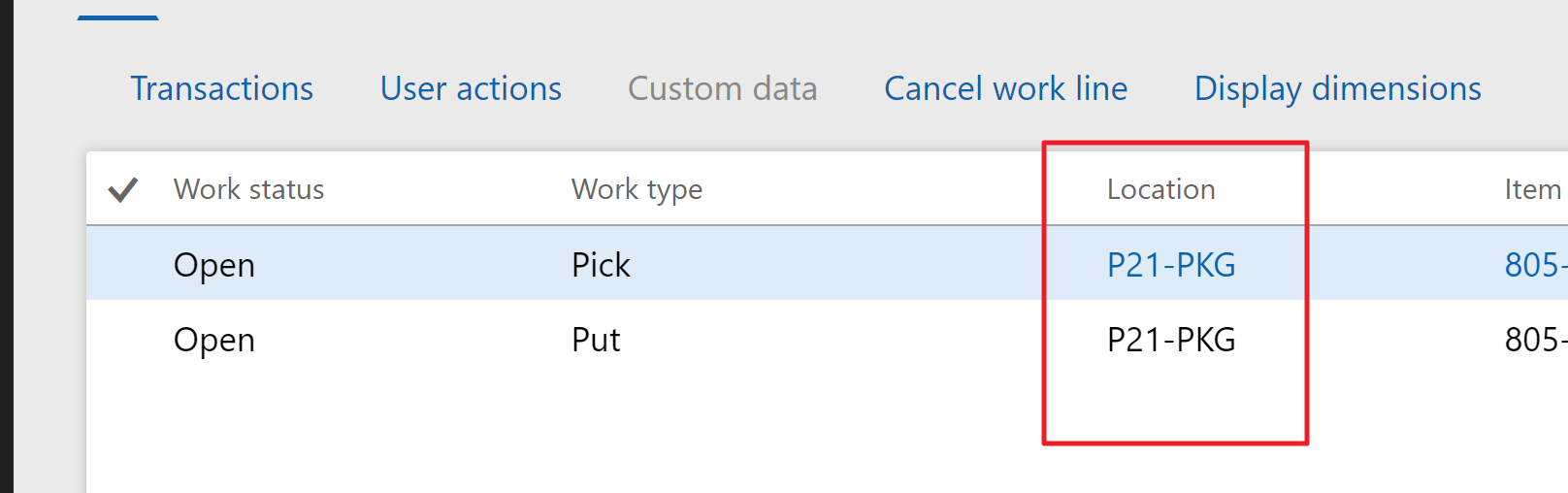

I have an issue with the production order raw material picking. For some reason, the system generates pick/put work for the same input location. The desired scenario is that when the Release to the warehouse process is triggered the system should automatically change formula line status to Picked if the input location has enough inventory. This works for 8 of 10 formula lines, but I still get pick and put work for the 2 formula lines. The main difference of the two rogue picks is that items being picked are non-batch controlled. Therefore, I have a separate non-batch location directive to support the pick.

Please let me know if anyone experienced a similar issue?

Thanks