Hi,

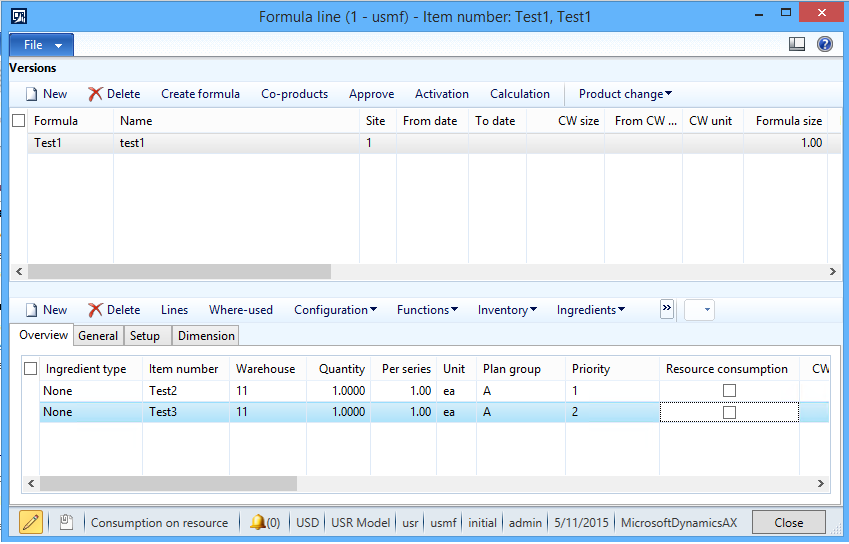

I have following formula for item Test1 :

I want to modelling formula like this : Item1 only needs 100 pcs of materials (it could be Test2 OR Test3). If one of those materials have insufficient stock, system will consider the availability of the alternate item.

Item Test3 is an alternate item for Test2, so I set the same Plan Group for both item and I give Test3 higher priority than Test2.

Test2 have 20 pcs on stock, and Test3 have zero stock. Then I create Sales Order 100 unit for item Test1. When I run Master Scheduling, system suggest to produce 100 pcs of Test1 and buy 180 pcs item Test3.

What I want is system only suggest 80 for item Test3, because it only need 100 pcs of the materials. Can anyone help me to make the right formula setup?

Thanks in advance

*This post is locked for comments

I have the same question (0)