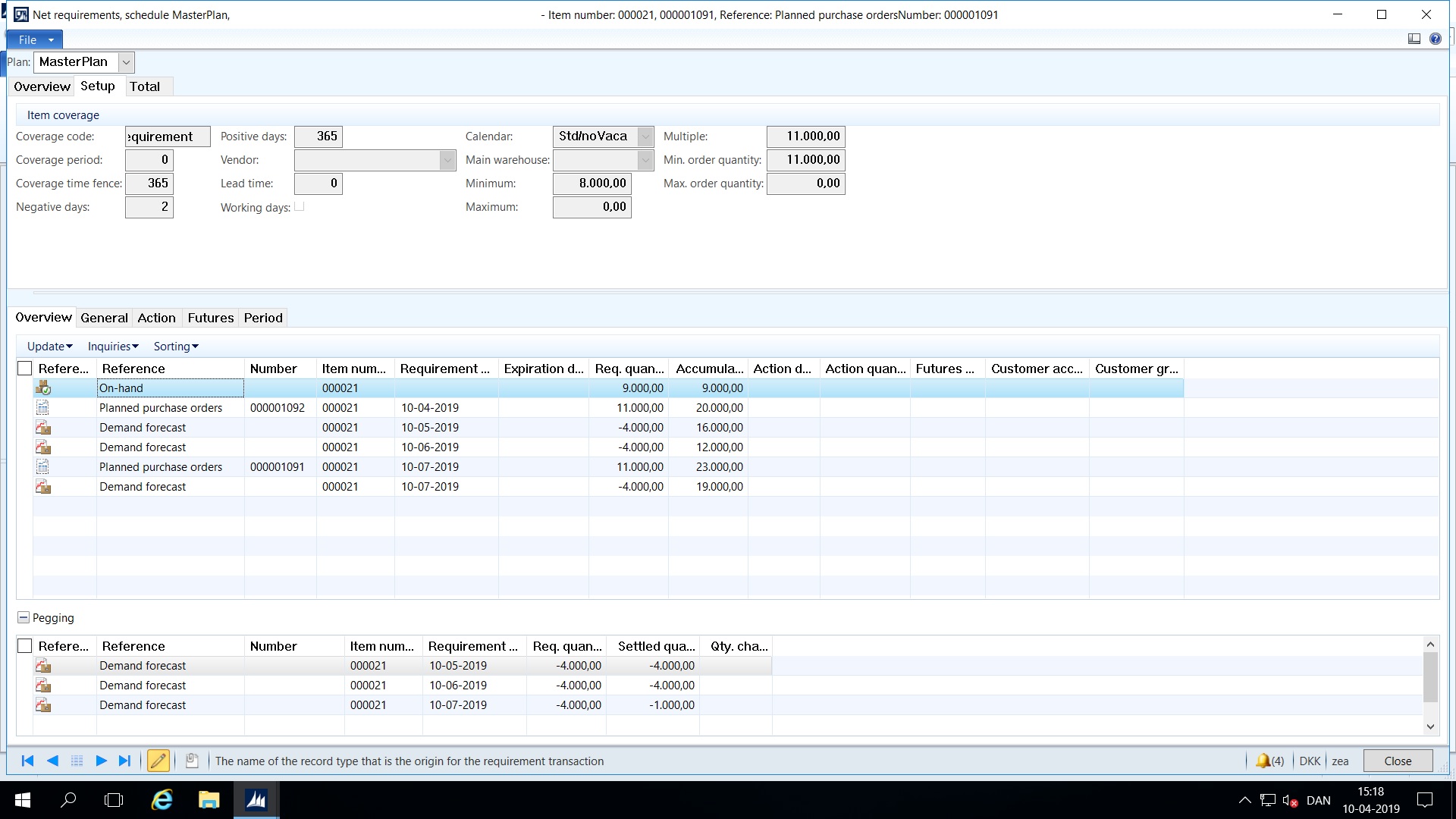

I have an item which has stock. For some reason, the MRP only pegs the onhand towards the actual sales orders or forecasts and then the MRP creates seperate POs for the safety stock. This PO is too early since it should not be needed before the next demand forecast.

I am also wondering why the planned PO for the safety stock is after (1092) the later planned PO (1091)

The "Fulfill Minimum" is set to be as per todays date.

Can anyone explain what the problem is?

*This post is locked for comments

I have the same question (0)