We use WilloWare's MO Generator to create a Manufacturing Order in Dynamics GP. It creates a MO in GP and processes it. In this case, 90 items of a raw material (an item on the BOM of the item the MO is for) is stuck in allocated. WilloWare suggested I run Component Transaction Entry and MO Receipt Entry, but I receive errors on both. The Component Transaction Entry shows a yellow triangle beside the raw material I'm having problems with and clicking Post gives the message "the transaction quantity is greater than the expected quantity needed". The MO Receipt Entry also gives a yellow triangle beside the quantity to backflush by the raw material I'm having trouble with and clicking Post gives the message "At least one component has a shortage that has been overridden". This is the extent of my GP knowledge. I'm a C# developer by trade and am only looking into this because I wrote the batch program that runs the WilloWare software. How do I get the items out of allocated?

Here is the raw item with 90 items stuck in allocated:

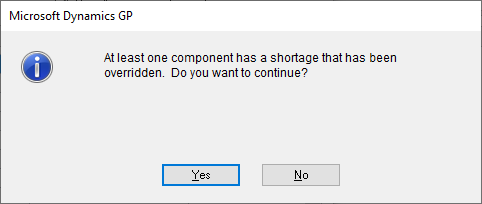

Here is the MO:

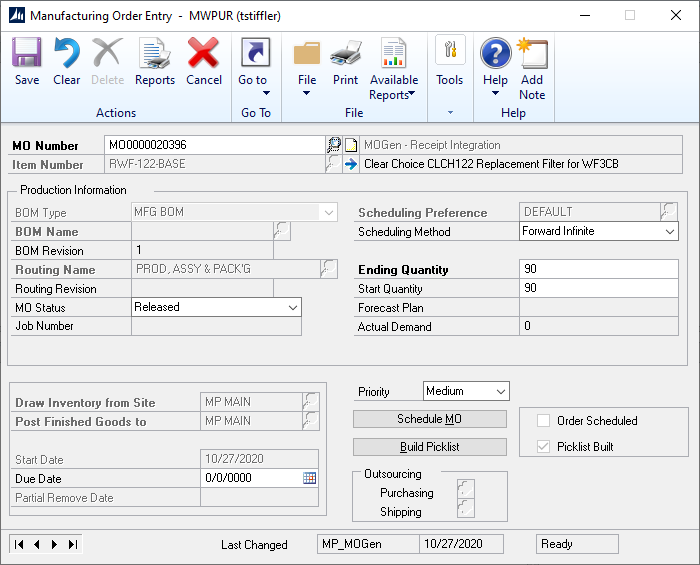

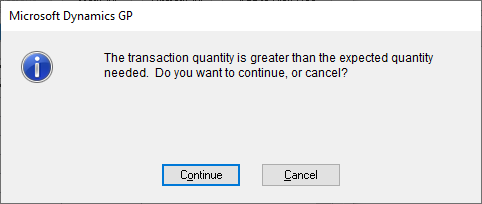

Here's the Manufacturing Component Transaction Entry and the error message:

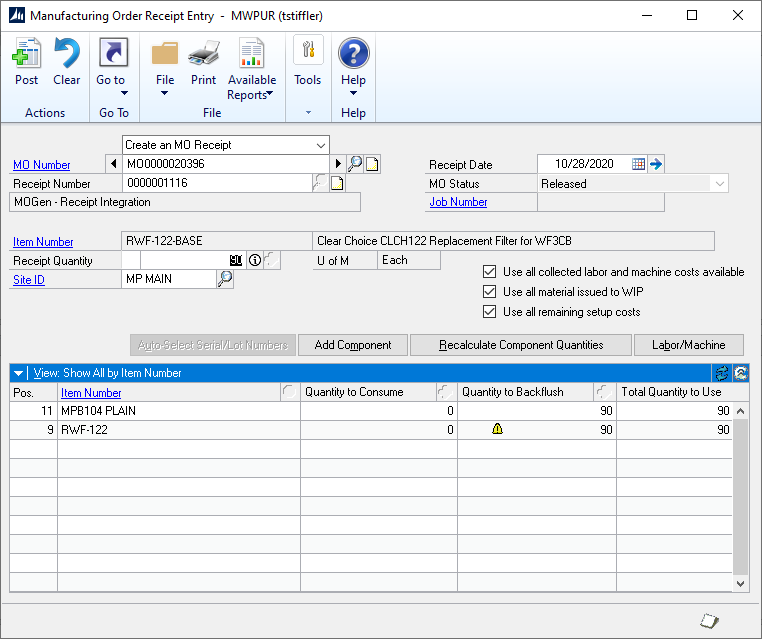

Here is the Manufacturing Order Receipt Entry and the error message: