Is it valid for a Min/Max replenishment to succeed (and create a Put line for the full required quantity) if there is not enough inventory of the item anywhere in the warehouse?

In my scenario, there are 15 x BAG118 in the Warehouse. The item has one Fixed location, which I am attempting to fill using Min/Max replenishment. The fixed location is empty. The Max on the replenishment template is set to 100. The location directive allows split, and is set to look at Bulk locations in order of lowest physical inventory first.

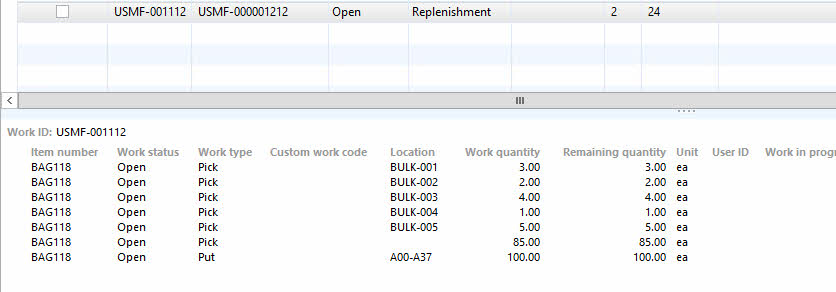

I run the Replenishments periodic job. It creates several picks from the bulk locations, and then a Pick with no location for the remaining 85. It also creates a Put for the full 100. Where does it imagine I'll get the 85 from?!

AX 2012 R3 CU8

*This post is locked for comments

I have the same question (0)